Some Design Aspects for Selecting Heavy Duty Apron Feeders

S. Das and A.K. Sahu, India

Courtesy : Trans Tech Publications - Bulk Solids Handling Journal

1. Introduction

Apron feeders are built today in various sizes and with a wide variety of components, to handle heavy and lumpy materials. In the past, apron feeders were manufactured to last for ever. However, due to cost effective design, emphasis is now being placed on return on capital [1]. The cost can be varied depending on user specifications and the design philosophy of the manufacturers. The specifiers can make an important contribution to the cost effectiveness of heavy duty apron feeders. Factors, such as the characteristics of material carried, capacity, length, method of feeder loading, degree of lift, hopper opening, pan construction and type of drive, all influence the cost effectiveness [1].

The extra heavy duty apron feeder is used at quarry bins, storage bins or bottoms of vertical shafts for lumps to be fed to the crusher. The feeder must be able to cope with strong failing impact loads, high raw material pressures and receiving resistances owing to the failing and jamming of large lumps, i.e., 500-2000 mm. Some of the Japanese extra heavy duty type apron feeders (Kurimoto) are so strongly designed and manufactured that they can be operated in a stable condition under extremely severe conditions.

Proposed Apron Feeder at Daitari Mines

The various features of the apron feeder proposed for Daitari Mines are as follows:

Load bearing peformance against falling impact load, hopper pressure is superior.

Feed rollers and chains are remarkably durable.

Specially processed feed rollers prevent wandering of apron.

Simple construction and the built in lubrication system eliminate squeaking and other abnormal sounds in operation.

Maintenance is easy. Only a short time is required to change the apron or conveyor chain.

Total operation and maintenance costs are low.

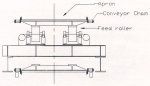

Capacities from 1.6 t/m for apron feeders for feeding crushed stone with varying bulk density, are available. Capacities and motor outputs vary depending on the length of apron feeder and the apron speed. These apron feeders are normally operated at variable speed. Motor capacities are designed taking the efficiency of the speed reducer, speed variator and the power transmitting system into account. Normal inclination is 80 upward. Fig. 1 shows the apron, conveyor chain and feed roller. Fig. 2 shows the various parts of an extra heavy duty apron feeder.

Fig. 1: Cross-section of apron feederFig. 2: Extra heavy duty apron feeder

1. Hopper skirt 2. Skirt 3. Head chute 4. Discharge chute 5. Frame 6. Tail wheel3. Design Parameters for Extra Heavy Duty Apron Feeder

Variation in systems and materials demands that each feeder be designed for its application, drawing on a wide range of components. Therefore, certain factors must be considered before final specifications are drawn.

3.1 Nature of Materials to be Crushed

The maximum lump size must be identified so that the pan width can be selected to accommodate the maximum lump. Usually two times the maximum lump size is considered as minimum width. However, if the maximum lump occurs rarely, the manufacturer must have the know-how to optimize the selection. Once the pan width is set the bed depth of the pan and chain speed must be balanced to develop a good design. Lump size, density and method of loading the feeders are considered when selecting pans. Impact rails are usually included in the hopper area when truck dumps onto the pan. Angle of repose is a definite consideration for specification. If the angle of repose is small, the feeder will have to be longer; a steeper angle of repose allows a shorter unit.

3.2 Capacity

The capacity of the apron feeder governs the capacity of the processing machinery, which in turn governs other equipment. Design, dimensioning and power calculation of the apron. feeder is based on the processing machinery.

3.3 Pans

Pan construction and materials are related to cost effectiveness. The effect of material size and density, impact, hardness and abrasiveness are reflected in pan construction materials. High manganese steel alloy is valuable for the heaviest impacting loads. Formed abrasion resistance steel is useful where abrasion and moderate impacting are present. Cast alloy steel is selected where moderate impact is involved. Rolled steel is useful for moderate impacting and high abrasion and also for lift.

3.4 lift

The feeder must overcome gravity in order to raise the material, which adds to the power requirement. Frictional force between the pan and the material also occurs. For newly developed, formed steel pans, the incline may be increased from 10 to 22.

3.5 Hopper Discharge Opening

The hopper opening is related to the power requirement. The longer the hopper opening, the more power is required to run the feeder. Hence, there has to be a live storage in the hopper which has to be balanced with the overall length and chain pull of the unit. The chain pull is the part of the power equation and it also determines the size of the tractor chain, the rollers, and the structural frame for the feeder.

3.6 Drives

Normally variable speed drives are used for heavy duty apron feeders, variable speed drives offer tremendous flexibility. Today's sophisticated variable frequency Eddy current drives can adjust the feeder speed to match process requirements.

4. Data For Selection of Apron Feeder

4.1 Determination of Feeder Capacity

4.1.1 Calculation of Capacity

Q = 60 x F x S x γ

Where F = Fm x a Q = feeder capacity t/h F = effective extraction area m S = apron speed mts/min γ = bulk density of feed material t/m Fm = total extraction area m a = extraction efficiency 0.75 for (0-8) 4.1.2 Allowable Speed

Apron speed is determined from the above formula for calculating capacity taking into consideration the standard service life of chain and apron, noise caused in operation and the desirable feeder speed for material to be handled

| Allowable Speed (mt/min) |

|

| High speed range long feeder |

max - 15 |

| Standard length |

Max - 10 normal - 2 ~ 6 |

| Low speed range |

min 0.1 - 0.1 or higher |

| Speed change ratio AC variable speed motor (VS or AS) |

1:10 |

| DC variable speed motor (DC) |

1:10 |

4.2 Apron Width and Size of Feeder Material

4.2.1 Blasted Quarry Stone

Usually, the thickness, width and length of blasted quarry stone have a ratio of 1:1.4:2 respectively - the length being denoted as the maximum edge length. Often, in continuous operation, quarried stone, larger than the specified length, is fed, which blocks the discharge outlet of the hopper and causes overload or damage to parts of the feeder. The maximum edge lengths allowable for the apron widths should be less than or equal to the apron width x 0.75.

4.2.2 Feed Material of Relatively Uniform Grain Size

Where many stones of the maximum size allowable for the feeder occur which may interfere with each other at the hopper discharge outlet, or when the feed material is of nearly allowable length, it is preferable that the maximum allowable length of feed material is equal to the apron width x 0.35.

4.3 Motor Requirement

4.3.1 Conditions for Calculation of Required Shaft Horsepower

Hopper pressure applied into the apron

inclination of the apron.

4.3.2 Operational Conditions

Maximum feeder capacity and range

Physical properties and bulk density of feed material

Apron speed.

Proper tension for the chain is obtained from the above conditions and the necessary shaft horsepower is calculated. The required shaft horsepower includes the starting power needed when the hopper is fully loaded.

4.3.3 Required Motor Capacity

The required capacity of the motor is obtained from the required shaft horse power as follows:

Nm = N/λ

| Where | Nm = required motor capacity kW |

| N = required shaft hp kW | |

| λ = transmission efficiency | |

| For AC variable speed motor λ = 0.65 | |

| DC variable speed motor λ = 0.8. | |

5. Modifications Suggested at Daitari

In order to avoid the problem of frequent blockage, it was suggested that the ROM ore should be fed to a primary crusher continuously, incorporating the following:

Installation of bar grizzly over the feed hopper to prevent boulders of 1,050 mm size from entering the hopper.

Increasing the hopper capacity from 50 t to 75 t by raising the walls, so that it holds three dumper loads of material.

Installation of a 1,500 mm wide apron feeder underneath the feeder hopper.

Provision of a live roll grizzly (multi-roll type) after apron feeder to separate out the -100 mm material.

Modification of the existing chute system to collect the undersize material underneath the live roll grizzly to feed to the gathering belt conveyor.

5.1 Technical Details of Modified Parts [2]

5.1.1 Fixed Grizzly

ISMB 500 x 180 x 5,000 mm, width 1,250 mm.

Grizzly bar made of structural steel fitted with austenitic manganese steel wear blocks.

5.1.2 Hopper

Capacity: 75t, top opening, 8,000 mm x 5,000 mm.

Bottom Opening: 1,750 mm x 1450 mm

Material of construction: structural steel, lined inside with manganese steel wear resistant plate.

5.1.3 Apron Feeder

| Capacity: | 800 t/h average |

| Size: |

1,500 mm width x 3,800 mm length |

| Speed: | 3.2 to 6.5 m/min |

| Drive: |

40 hp at 1,500 rpm induction motor with Eddy current drive |

| Material of Construction |

Manganese Steel. |

5.1.4 Skirt Board

The sides of apron feeder and live roll grizzly are lined with skirt boards made of mild steel lined inside with rubber lining and manganese steel plate lining.

5.1.5 Chain Pendulum

To control the feed of boulders to the live roll grizzly, a chain pendulum made of structural joint with four manganese steel chains, fixed at upper end to a beam, is provided.

5.1.6 Live Roll Grizzly

| Capacity: | 1,200 t/h maximum |

| Size: |

1,500 mm (width) x 2,700 mm (length) |

| Slope: | 22 to horizontal |

| No. of rollers: | 70 |

| No. of roll shafts: | 7 |

| Drive: |

20 hp at 1,000 rpm, motor fitted with differential gear box |

5.2 Salient Features of Extra Heavy Duty Apron Feeder

High load carrying capacity against impact and pressure loads.

Long service life of conveyor chain.

Rigid construction.

Easy maintenance.

6. Conclusion

The modified system of iron ore handling plant installed at Daitari incorporating an extra heavy duty apron feeder has immensely benefited M/s Orissa Mining Corporation Ltd. The plant achieved a capacity of 800 t/h without any of the diffuculties experienced earlier, such as frequent shutdown of plant due to choking of the chute system.

Apron feeders are now considered to be very important in the entire system. of iron handling plant. The selection of the apron feeder has been greatly optimized. The manufacturer should be helped to select the correct size and capacity by developing engineering criteria.

Acknowledgement

The authors are very grateful to the Director, Regional Research Laboratory, Bhubaneswar for permitting the publication of this paper, and to M/s Orissa Mining Corporation Ltd., for sponsoring the assignment. The authors are grateful to various officials of OMC, in particular Sri M.S. DAS, Sr. Materials Manager.

References

SCUDAMORE, S.R.: Develop specifications before selecting heavy duty apron feeders; Mining Engineer, Dec. 1983, pp. 1619-1620.

DAS, S. et al.: Modification of an Indian iron Ore Handling Plant; bulk solids handling Vol. 10 (1990) No. 4, pp. 413-415.

Mr. Shri S. Das and Mr. A.K. Sahu, |