Conveyor Watch - Company Profile

Source: Bulk solids handling

Conveyor Watch, based in Johannesburg. Republic of South Africa, specialises in the evaluation or conveyor systems. Over 400 conveyors have been investigated internationally since the inception of the service in 1983.

With new conveyor designs being pushed beyond existing operating levels, it has become imperative that the designs are verified to ensure that eac system performs as per specification.

Total System Assessment

Conveyor Watch undertakes unbiased performance assessments, independant of the user, designer and equipment suppliers. These are valuable for hand-over certification and also provide a signature or blue print for future reference should problems occur during the life span of the system.

The service is beneficial for checking existing conveyor systems where problems are being experienced or where upgrading is being contemplated. It is also useful for preventative maintenance monitoring.

With conveyor designs becoming more complex and innotive, a demand for more accurate and more detailed information has resulted in Conveyor Watch's development of a sophisticated yet compact measurement package. The instruments are easily installed on any conveyor configuration, with minimal interference to production.

The system identifies:

Maximum and minimum T2, Te and T1 belt tensions

Tension distribution for tripper/linear booster systems

Starting and stopping dynamic transients

Belt safety / service factors

Loading trends, load sharing and tonnage relationship

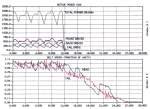

Drive performance including power, current, voltage, power factor and drive slip (Fig 1)

Take-up performance

Belt tracking and splice condition.

Fig. 1: Typical capture of problematic event

Conveyor Watch has experience in all types of conveyor configurations including:

Surface Installations

In pit overburden removal-sand stripping systems

Overlands, including systems with head to tail drives - up to 8km centres (Fig. 2)

High angle and downhill systems

High power inclined systems, with tonnages up to 15,000 t/h

Fig. 2: Typical installation of the system on a 10,000 t/h overland systems with head and tail drives

Underground Installations

Armoured Face Chain conveyor systems

Longwall Panel and Trunk conveyors including systems with intermediate drives - up to 7km centres with solid woven belting. (Both tripper and linear configurations.)

New Monitoring System

Conveyor Watch has developed a new Monitoring System for mines wishing to do their own performance testing. The kits include:

Rugged industrial computer or opinion of using a notebook with PCMCIA interface.

User friendly Windows 95 based software.

Durable universal transducers for measuring belt speeds, drive slip, take-up tension and displacement.

Modular motor drive performance transducers.

A portable kit is available for short duration tests on numerous conveyors (Fig. 3). Alternatively, a permanent installation system can be used for monitoring critical applications such as:

Fig. 3: Portable conveyor monitoring system

Man riding conveyors

Conveyors where high speed data capture of events is required, such as splice failures.

Equipment failure analysis and preventative maintenance monitoring.

Steel Cord Belt Condition Monitoring

To complement the total system assessment, Conveyor Watch offers this additional service. To date, over 300km of steel cord belt has been scanned. Using magnetic induction techniques, this service identifies:

Location and extent of broken or damaged cords

Location and extent of rust damage

Splice condition via magnetic signature evaluation

Cover wear and life prediction.

A remote Monitoring System is available for permanent installation on critical conveyor systems.