| Features of a Sicon Conveyor |

|

Sicon bend / drive stations

Bend stations enable the belt to be deflected at almost any angle up to 180 degrees.

Depending on the Sicon conveyor belt employed, the bend radii for the Sicon belts is :-

| i |

S100 Sicon belt |

: |

600 mm radius. |

| ii |

S1000 Sicon belt |

: |

1000 mm radius. |

Where the belt path is to be deflected only slightly i.e. up to say 20 degrees, then a smaller deflector pulley may be used, which occupies a smaller space. These deflector pulleys are generally approximately 400 mm in diameter.

The choice of bend pulley to use depends on the following criteria :-

-

Orientation of belt

i.e. whether the pulley should be a grooved pulley or flat pulley to interface with the Sicon belt as depicted in the following sketches.

-

Function of the pulley

i.e. whether the pulley is a drive and bend pulley or purely a bend pulley.

It is generally preferred to use grooved pulleys when the pulley is to be used as a drive pulley.

For this reason the selection of the location of a drive unit usually takes this into consideration.

|

Combination drive and bend pulley |

Bend pulleys without drives may be grooved or flat, depending on the orientation of the belt.

Where the wrap angle on a pulley is 180 degrees for example at the head-end of the conveyor, this is an ideal position to install a drive unit as it makes optimum use of the large wrap angle.

-

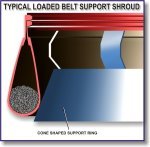

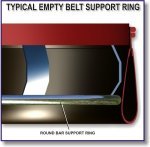

Loaded or empty belt

i.e. depending on whether the belt is carrying material or is on a section of the conveyor where no load is ever transported, the pulley shroud or 'cone' differs.

The reason for the difference in the use of either a cone (seen adjacent) or a round support bar is a function of the type of support which the belt requires as it bends around the pulley.

It can be seen in the sketches that a loaded 'bag' requires the conical support to ensure that the centroid of the load and hence the belt's bag section, is virtually always at the same radius, irrespective of the load transported at the time.

On the return / empty strand, the belt can be supported in a more simple fashion.

In addition to the 'bend' and 'drive' pulleys, a Sicon conveyor also includes a series of pulleys at the discharge points, to support the belt through the tripper-type discharge.

These pulleys also comprise 'V' grooved pulleys and flat pulleys, depending on which of the two profiles the pulley is to support.

Discharge points are discussed in more detail below however, the diameter of these pulleys varies for the different belt classes as follows :-

| i |

S100 Sicon belt |

: |

650 mm diameter. |

| ii |

S1000 Sicon belt |

: |

1200 mm diameter. |

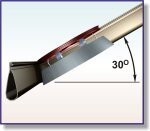

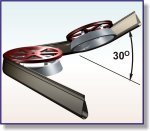

As far as the design and layout of a bend station is concerned, it is important to orientate the belt in such a fashion as to ensure that the belt feeds onto- and off of the pulley tangentially, as indicated in the following sketch.

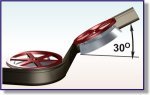

Where the belt is required to turn through 180 degrees and at the same time go through a transition to an incline, the bend station must comprise two pulleys as indicated in this sketch.

In this instance the first pulley is horizontal where the belt feeds onto the pulley and exits at 90 degrees, tangentially.

The belt thus feeds onto the second pulley tangentially and this pulley is inclined at 30 degrees along one plane, to allow the belt to exit at 30 degrees, tangentially.