Features of a Sicon Conveyor

Sicon discharge station

Sicon conveyors have a number of different discharge configurations which can be considered for any particular application.

The following layout is however the 'standard' tripper-type discharge and is the most widely used and technically preferred arrangement.

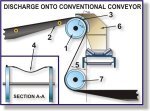

In this layout the belt is opened gradually from its closed formation and is threaded onto two vertical head pulleys (1) which are angled to suit the opening, loaded belt (2).

The belt is never stretched to its maximum width when it passes over the discharge (3). Instead, a 'crease' or 'wave' (4) is formed in the 'bag' section of the belt, which serves to eject the material from the belt as the bag wraps around the crease. This feature is extremely effective in cleaning the belt.

From the 'head' pulleys the belt is drawn back to a tangent point beyond the vertical plane (5) to allow the material sufficient opportunity to discharge into the head chute (6).

Two additional vertical pulleys (7) then deflect the open belt forward and at the same time, assist the belt in closing again.

The tripper-type discharge station holds the opportunity to discharge product into a range of equipment or bins as indicated in the sketches below.

The tripper-type discharge is also a convenient method used to route the belt from an elevated position to ground level.