Features of a Sicon Conveyor

Sicon loading stations

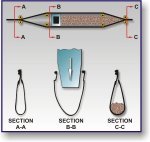

An example of a loading station is provided in the sketch.

The Sicon is normally closed (A-A) however, at the loading point the two belt profiles are gradually parted and the belt is 'opened', ready for loading.

The layout of the loading station is such that the feed chute, skirt plates and skirt rubber can be accommodated while at the same time ensuring a reasonable seal.

Material is fed into the center of the open belt (B-B). There are no impact idlers and thus the feed system must ensure that the drop height onto the Sicon is as low as reasonably possible.

It is also important to bear in mind that the Sicon conveyor, like the pipe conveyor, has a maximum volumetric capacity imposed by the fact that the belt closes to a finite cross-sectional area.

If the conveyor is over filled, the belt will be tripped by the overfill detector and before re-start, the overfilled section must be cleared before the belt can be re-started.

Once the load has been fed into the conveyor, the belt closes and the product is enclosed (C-C).

The length of the loading point depends upon the number of feed points and the belt speed. The belt is kept open after the last loading point for sufficient time to :-

Detect whether the belt has been over filled. This is determined by the over-fill detector (a) which trips the conveyor in the event of an overload.

Allow sufficient run-down time to bring the belt to a stop before the belt is 'closed' and damage is done resulting from an overload.

Where dusty products are conveyed in the Sicon, it is recommended that a de-dusting facility be provided, to exhaust the displaced air and air-borne dust.

The Sicon's loading station is extremely efficient in terms of its ability to contain dust. It is however sometimes advisable to provide dust extraction.

The feed into a Sicon conveyor should always be regulated or controlled as explained above. Depending on the specific application, feeders could include vibrating feeders, rotary valves, tube feeders, belt feeder and so on. The feed chute work can be adapted to accommodate the applicable feeder type.