|

Engineered Transfer Point Technology |

|

Contents

- A. The Pyramid Approach

- 1. Entry Area

a. MARTIN TRACKER Belt Tracking System

Adjusts conveyor belt alignment precisely and continuously.b. Martin Services Laser Surveying

Provides a high-tech analysis of conveyor defects.c. MARTIN REVERSING TRACKER System

Prevents mistracking on belts that run in two directions.d. MARTIN Tailgate Sealing Box

Ends material rollback off the end of the conveyor.e. MARTIN Tail Pulley Protection Plows

Prevent damage from material on the belt return. - 2. Loading Zone

a. APRON SEAL Skirting Systems

Provide an effective, low maintenance dual seal.b. GUARDABELT Impact Cradles

Cushion and stabilize the belt in the loading zone.c. TRAC-MOUNT Idlers

Support the belt while improving ease of maintenance.d. GAURDASEAL Belt Support Cradles

Eliminate belt sag to prevent material spillage.e. DURT TAMER Wear Liner

Forms a dam to protect the sealing system from the load. - 3. Exit Area

a. MARTIN FOG Dust Suppression

Controls dust with microscopic water mist.b. MARTIN FOAM Dust Suppression

Provides residual dust control with low moisture addition.c. MARTIN Water/Surfactant Dust Suppression

Adds chemicals to water spray for improved dust control.d. MARTIN Insertable Dust Collectors

Install above loading zone to collect dust without ducting.e. MARTIN Dust Bag

Supplies passive dust collection in positive air pressure.f. MARTIN Dust Curtains

Slow air movement for effective dust control.

The Pyramid Approach

With over 50 years of experience in making bulk material handling cleaner safer and more productive Martin Engineering offers practical solutions to your belt conveyor problems.

By preventing spillage and airborne dust, Martin Engineering's Transfer Point Technology will reduce equipment damage, reduce cleanup, and control maintenance expenses.

But Martin Engineering is more than an equipment supplier. We have created and implemented a comprehensive approach for putting a stop to fugitive material. This system incorporates improved systems for Material Containment, Dust Suppression, and Dust Collection. It also includes significant contributions from the intangibles of Commitment, Knowledge, and Service. This philosophy is explained in Martin Engineering's book FOUNDATIONS2 The Pyramid Approach to Control Dust and Spillage From Belt Conveyors.

This page highlights the various hardware systems offered by Martin Engineering as components of the Pyramid Approach.

For more information about improving transfer points with The Pyramid Approach, see your Martin Engineering representative.

1. ENTRY AREA

In the entry area, the belt is prepared for loading. Here, the belt must be centered, wrapped around the tail pulley, and formed into a trough.

Keep the Belt Tracking True

To end mistracking, the patented MARTIN TRACKER Belt Tracking Systems automatically sense and continuously correct belt tracking. Use upper unit on carrying side of belt; install lower unit on return side.

MARTIN TRACKER Belt Tracking Systems

- Continuous Belt Alignment

Improved tracking reduces edge damage, spillage, and maintenance expense.

- Works Where Other Systems Fail

Continuous precision adjustment of the patented parallel steering / training system keeps the belt tracking perfectly.

- Guaranteed To Keep Your Belt On Track

Follow our recommendations for installation and maintenance of a complete system, and Martin Engineering gaurantees perfect tracking forever.

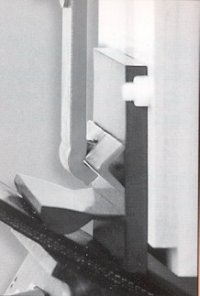

Light touch of belt against guide roller creates precision corrections.

Patented tie rod aligner translates action of steering bars to training idlers on both upper and lower units.

Three sizes fit belts to 72 inches (1800-mm) wide.

High-Tech Technique for Conveyor Alignment

Laser Surveying from Martin Services

Specialists from Martin Services use laser systems to survey conveyor components and determine precise corrections to prevent conveyor problems.

Keep Reversing Belts in Alignment

The MARTIN REVERSING TRACKER System provides precision correction of mistracking on conveyors that run in two directions.

MARTIN REVERSING TRACKER Belt Tracking System

- Works In Both Directions

Unique dual sensing mechanism keeps the belt centered no matter which direction the belt is running.

- Self-Adjusts To Match Belt Direction

A stainless steel "paddle wheel" senses the direction of travel and switches to the proper steering guides.

- Precise, Positive Correction

Steered by the edge guides, the MARTIN REVERSING TRACKER makes continuous corrections to train reversing belts.

End Material Rollback

With an effective seal before the load zone, the MARTIN Tailgate Sealing Box solves the age-old problem of material escaping out the back of the transfer point.

MARTIN Tailgate Sealing Box

- Prevents Material Rollback

Seal keeps material from sliding off the belt.

- Avoids Material Buildup

Belt motion deflects tail seal to prevent accumulation at back of box.

- Simplifies Cleanup

Dust-tight, easy-opening Steel CYA Inspection Door provides simple access.

- Installs Easily

Field-welded onto chute wall to ensure precise fit.

Protect Conveyor Components

Protect pulleys and the belt from material impingement by installing a MARTIN Plow.

MARTIN Economy V-Plow

- Adjust Weight To Match Conditions

Fill molded tank with ballast to keep plow steady on belt.

- Effective & Economical

Simple solution for basic applications.

MARTIN Standard V-Plow

- Effective Tail Pulley Protection

Removes material before belt enters the tail pulley.

- Economical Solution

For less demanding applications.

MARTIN TORSION ARM V-Plow

- Maintains Cleaning Pressure

Arms provide self-adjusting action for effective cleaning in all stages of blade wear.

- Safe For The Belt

Three-point suspension keeps the plow parallel to the belt.

- Easily-Replaceable Cleaning Blade

Available in rubber or urethane.

MARTIN Diagonal Plow

- Protects Reversing Belts

Diagonal plow protects pulley in both directions of travel.

- Cleans Without Adjustment

Plow drops into brackets on either side and floats on belt surface.

DURT DOZER Plow

- Pushes Material Off The Belt

Curved blade installs at angle across belt to remove material

- Double Wear Life

Turn the two-edged blade over to double the service life.

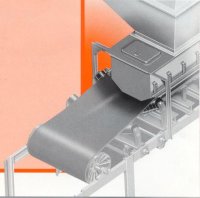

2. LOAD ZONE

In the load zone, material is placed on the belt. Here, the belt must be properly supported and sealed to recieve the cargo and prevent spillage.

Form Low-Maintenance Dual Seal

Patented, dual-layer APRON SEAL Skirting provides a transfer point seal that is effective and economical, and built to stay that way.

APRON SEAL Skirting System

- Dual Seal Effectiveness

Seals without high pressure on the belt.

- Primary Seal Forms Inner Barrier

Keeps material inside the chute.

- Secondary Seal Captures Fines

Ribs carry fines down the belt.

- Minimal Adjustment

Internal elasticity provides sealing force.

- Long Life, Low Maintenance

Low pressure means effective performance over long life.

- Systems To Fit Needs

Available in "Original" 2-piece, Standard 1-Piece, and Heavy-Duty 1-Piece Systems, to match application.

- Provides Continuous Seal

1-Piece Systems available in lengths to 300 feet (91.5 meters).

- Ideal Replacement System

Works with virtually any clamps.

|

|

Standard 1-Piece APRON SEAL Skirting System |

|

|

Heavy-Duty 1-Piece APRON SEAL Skirting System |

Absorb Loading Zone Punishment

GAURDABELT Cradles cushion loading zone impact, preventing damage to belt and structure, and stabilizing the belt line to control spillage.

GAURDABELT Impact Cradles.

- Reduced Power Consumption

Belt runs smoothly over low-friction UHMW top layer.

- Protects The Belt

Secondary layer of 50-durometer rubber absorbs high-energy impacts.

- Simple To Service

Impact bars slide into position in TRAC-MOUNT Cradle.

- Long-Lasting Construction

Rugged steel framework stands up to rugged conditions.

- Fits Your Conveyor

Cradles available in standard and wide base in any troughing angle.

Keep Belt Rolling

Patented TRAC-MOUNT Idlers use sliding frames to fit in tight spaces between cradles, ensuring proper rolling support for the belt.

TRAC-MOUNT Idlers

- Simple Service

Individual rollers slide in and lock in place from outside the belt. No more laying idler sets on their side.

- Proper Support In Tight Spaces

Slide-in frames need only 8 inches (203 mm) of width for 6-inch (152 mm) rollers.

- Meets CEMA Standards

Available for any belt width or troughing angle, with any brand of rollers.

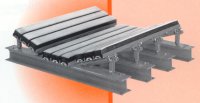

Stabilize Belt Line and Stop Spillage

Installed under the belt outside the impact zone, GUARDASEAL Belt Support Cradles eliminate sag to stop material escape, reducing maintenance and cleanup.

GUARDASEAL Belt Support Cradles

- Supports The Belt For Sealing

Cradles support belt edges, allowing effective seal.

- Protects The Belt

Cradles eliminate pinch points where trapped material can gouge the belt.

- Reduces Horsepower

Belt glides over UHMW bars without heat buildup.

- Double Wear Life

Use both top and bottom of unique "box" bar.

- Simple To Service

Cradle adjusts for wear easily with simple tools.

- Cradles To Fit Conditions

Fits any troughing angle. One bar per side for belts 18 (400 mm) to 42 inches (1200 mm); wider belts require two bars per side. Center bar or rollers may be required.

Protect Sealing System

To improve sealing efficiency, DURT TAMER Wear Liner creates a dam that keeps the material load away from the seals.

DURT TAMER Wear Liner

- Materials to Match Application

Available in mild, abrasion-resistant, stainless and ceramic-faced steel, and UHMW.

- Simple Installation

Supplied in 6-foot (1.83 m) lengths with pre-drilled holes. UMHW liner is 4 feet (1.22 m) long.

3. EXIT AREA

The exit area is where the loaded belt leaves the transfer point. Here, the material is settled and dust is contained, suppressed, and/or collected.

Control Airborne Particles with MARTIN Dust Management Systems

Cut cleanup costs, equipment failures, and regulatory problems with Martin Engineering's dust control technologies. These engineered answers to airborne dust keep fine particles in the load, or return airborne particles to main material body.

MARTIN FOG Dust Suppression System

Produced by forcing water through nozzles, this microscopic mist merges efficiently with dust to return material to main material body.

- Low Operating Costs

No chemicals needed; the only power consumed is for the pump.

- Minimal Water Added

Lowest moisture of any suppression system prevents material degradation and thermal penalty.

- Turnkey System

Specialists engineer, install, and tune the system for optimum performance.

MARTIN FOAM Dust Suppression System

Proportioner supplies proper amount of air, surfactant, and water to generate foam for suppression of even hydrophobic dusts.

- Minimal Moisture, Minimal Chemicals

Foam system expands water using minimal chemicals, for superior results with reduced operating costs.

- Residual Control

Surfactants provide long-lasting suppression all the way through the plant.

MARTIN Water/Surfactant Dust Suppression System

Custom mix of surfactant and water is spray-applied to meet your dust management requirements.

- Long-Lasting Control

Additives offer residual benefit to minimize the number of application points.

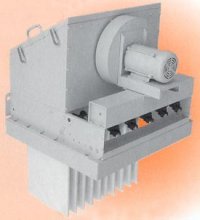

High-Efficiency Collection Without Ducting

Installed inside the enclosure, insertable collectors effectively handle the heavy concentrations of dust and high volumes of air arising from belt conveyor transfer points. Use as stand-alone collectors, or to supplement existing central systems.

MARTIN insertable Dust Collectors

- Return Dust To Main Material Body

"Reverse jet" pulse knocks accumulated material off filter envelopes to return dust to system.

- High Efficiency, Low Operating Cost

Filter envelopes provide 99.9 percent collection efficiency; small fan means low power consumption.

- Compact Design, Low Maintenance

Small "footprint" reduces space requirements. "Clean side" access for filter change.

Collect Dust, Relieve Pressure

Passive dust collection uses filter bag to vent positive air pressure while collecting dust. Suitable for use where airflow is below 1000 cfm (28,000 1/min).

MARTIN Dust Bags

- Exhausts Air, Retains Dust

Passive filtration system cleans air without mechanical collection.

Reduce Dust by Slowing Air Flow

Installed near the end of the transfer point enclosure, MARTIN Dual Dust Curtains slow ir velocity, reducing dust capture and retention by air currents.

MARTIN Dual Dust Curtains

- Adjusts To Material Flow

Curtains conform to load without pushing material off the belt.