| Process Automation Technical Data |

|

These user friendly belt scales offer superior weighing performance with extreme ease of installation. Counterbalanced with on-board test weight, makes calibration and maintenance easy. The weighing system may be expanded to suit the users requirements and budget.

LOW COST

ON-BOARD TEST WEIGHT FOR

QUICK CALIBRATION CHECKING

TRULY COUNTERBALANCED SYSTEM

COMPACT DESIGN REQUIRES LITTLE SPACEOPTIONS

BELT SPEED COMPENSATION

P.I.D. CONTROL

U-NET SCADA SYSTEMConstruction: Single Weigh idler, counterbalanced, approach type weigh frame of welded steel construction (stainless steel optional) with maintenance-free pivots.

Mounting: Stringer mounted, low profile, mounts in place of a standard conveyor idler.

Load Cell: Precision strain gauge carrying load in tension to provide immunity to load shifting. Optional mechanical protection against overload.

Idlers: For high accuracy, weigh class idlers are essential on the weigh platform (leading to, on and after the scale).

Signal Processor/Transmitters

Many transmitter models to choose from, to suit users requirements and budget

(see separate brochures for full details on these transmitters/indicators).

Construction: Cast aluminium

Measurement range: 24-1000 RPM / 1 - 50 RPM (optional)

Output: High-resolution digital type with RS-422 frequency output capable of being up to 500m from the weighing transmitter.

Protection Rating: P 65 standard (flameproof optional).

Tachometer (optional)

Mounting: To any non-driven pulley. Precision tachometer drive assembly available as an option.

Tachometer Drive Assembly (optional)

INSTALLATION CRITERIA FOR ALL ELECTRO-MECHANICAL CONVEYOR BELT SCALES

All PROCESS AUTOMATION UNIPRO electro-mechanical belt scales use the same key components, i.e. load cell, tachometer and signal processor. Performance varies according to the length of the weigh carriage and the conveyor/application conditions, being, application sensitive devices

- Conveyor Conditions:

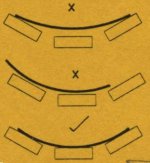

- The conveyor to be straight, having no concave or convex curves near the point of scale installation. For best accuracy convex curves should be not closer than four meters and concave curves not closer than fifteen meters from the belt scale. The needs of each application determine the exact distances, which can be tolerated. Consult the factory, providing a conveyor drawing or accurate sketch.

- The conveyor may be inclined, but the angle of inclination must be such that the material will not slide back on the belt, even when wet i.e. the material must always travel at belt speed.

- The conveyor to be stable well supported on sound foundations with adequate stringers and rigid idler frames. Within the scale installation area the stringers must be continuous. Welded joints are acceptable. Cable suspended and stacking conveyors should be avoided.

- Trippers, if any, not to come closer than twenty meters from the scale.

- The belt tension should be controlled by a gravity type take-up or equivalent.

- Idlers should be rigid and preferably of the three roll in-line types.

- Scale Installation Area:

- The scale should be installed in the low belt tension area, preferably five idler spaces from the loading point. There should preferably be only one loading point for the conveyor.

- The scale should be protected from wind and rain. Wind blowing on the scale can cause serious errors in some installations.

- There must be no skirt boards or anything else to interfere with the belt, scale or material on the belt at the point of weighment. Bend and snubber pulleys for the drive or tensioning devices situated below the scale may also cause problems.

- The Belt:

- The belt should be a standard rubber belt without stiffeners, pockets, etc., suspended on a conventional stringer and not rope suspended/driven.

- Belt tracking should be good, no belt tracking devices to be used in the vicinity of the scale.

- The belt must be sufficiently flexible to contact all idler rolls when unloaded and should be of a duty (weight) to suit the load. Very light loads require light belts.

- The belt can have a degrading effect if it is in a very poor condition causing spillage, etc. Poor belts can often be successfully used, depending on length, speed and some other conditions of the application, but need special consideration in any event.

- Use Requirements:

- The scale becomes less accurate nearer belt empty conditions. For better accuracy's the tied rate should be controlled between 50 % and 90% of calibration capacity. The correct selection of the type of scale becomes important if the belt is poorly loaded, often runs empty or the load in cycling.

- Vibration is damaging to most equipment and instruments. Severe vibration requires special consideration. Conveyors should always be isolated from vibrating screens, crushers, etc.

- Weigh class (duty) idlers are essential for high accuracy's and mandatory for certification. Scale-born idlers need special consideration since not all idler types can be modified to fit on the scale carriage. Standard idlers can often be used for medium to low accuracy applications. Troughing angles in excess of 35 degrees require special consideration.

- Calibration should ideally be done with live material, which is pre- or post-weighed. If this cannot be done, the possible alternatives should be discussed with a PROCESS AUTOMATION engineer to ensure satisfactory and cost-effective calibration.

- General:

Consult with the local PROCESS AUTOMATION representative to ensure that your weighing requirements are cost effectively met.

Conclusion:

Often compromises have to be made where the required criteria cannot be met, which means that compromises must also be made with respect tot he performance of the equipment

The golden rule is - Be as serious in meeting the required criteria for good weighment as you are about the required accuracy and performance of the belt scale.

TRUCK LOADING/BATCH WEIGHING SYSTEMS

INDUSTRY: Material handling/Mining/Chemical/Cement

PROCESS: Dispatching controlled quantities of materials.

PROBLEM: There are normally limitations on the legal loading permitted on road and rail trucks. Prevention of overloads has other benefits as well, yet economic sense requires that trunks be loaded to the maximum legal or safe limits. Bulk density variations makes volumetric controls unreliable.

SOLUTION TO THE PROBLEM: Weighfeeders or conveyor belt scales fitted with batch controllers will ensure that trucks are loaded to closely controlled limits. Batching of quantities of materials is also done to control final product quality.

EQUIPMENT USED: Process Automation manufactures a range of on-line batch control systems and weighfeeders. Loss-in-weight feeders, belt feeders, solids flow meters and bin weighers all make use of our universal Unipro signal processors. These user-friendly gauges ensure ease of operation and a low cost of ownership.