| Process Automation Technical Data |

|

LEVEL CONTROL ON FEEDERS, ORE PASSES AND SILOS

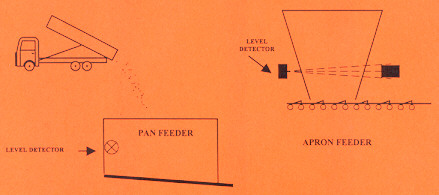

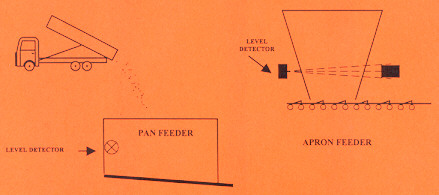

| INDUSTRY | Mining / Materials Handling / Cement / Ore Processing | |

| PROCESS | Feeding process material to and from storage. | |

| PROBLEM | Rocks falling on feeders or bottom of silos, may cause damage due to the direct impact. | |

| SOLUTION TO THE PROBLEM |

It is general practice to leave

a cushion of process material at the bottom of silos, on feeders

out of silos and in ore passes. |

|

| EQUIPMENT USED |

The Process Automation series NPL 300

point level gauges are extensively used as Low-Low level detectors to detect extreme low levels which may not be exceeded. These level detectors may be used to automatically stop the outfeed of process material to ensure that sufficient material remains behind in the silo to cushion the fall of new incoming material. Pan feeders, apron feeders, vibratory feeders and other feed/storage equipments can be protected by the use of the Process Automation NPL 300 low level gauge. |

|

| SELF-CHECK FACILITY |

In an application where the chute/pipe

feeder/ore pass etc. must never be allowed to go empty, the Low

Low Level Gauge is intended to almost never have to operate i.e. the source will always be shielded off from the detector by process material except under dangerously faulty process conditions. How will one know whether the detector is

still in good operating condition and will give the alarm

Our complete system check

monitors 100% of the detector unit, from the gamma detector tube

to the |