| Beginners Guide |

|

Information Sources:

Van Reenen & Nichols

Poly Hi Solidur

Multotec

Why Line ?

Chutes, silos, bins and hoppers are lined for two main reasons:

1. To protect the chute plates from excessive wear.

2. To improve the flow of material across the chute plates.

1. Protecting chute plates from Wear

The three main types of abrasive wear which occur

in mining and earth moving may be classified as follows:

|

|

SCRATCHING

|

|

|

GOUGING

Large particles move about over a steel surface under high pressure combined with hard impacts. |

|

|

GRINDING

Small Particles are pressed between two steel surfaces. |

Mineral Hardness

When the average hardness of the materials is lower than that of the wear plate, the plate is exposed to only moderate wear.

However, when the hardness of the material is higher than that of the

wear plate, a wearing-down process begins. The harder the minerals the more rapid the wear and, generally,

the harder the wear plate the greater the wear resistance.

Hardness of some minerals in Vickers (HV)

Calcite 140 HV

Flourite 190 HV

Apatite 540 HV

Felspar 600 - 750 HV

Flint 950 HV

Quartzite 900 - 1 280 HV

In comparison, ROG LAST AH360

has a hardness at 360 - 390 Brinell (equivalent 380 - 400 HV).

Other factors affecting wear resistance

Other factors which affect

wear resistance of materials are:

1. Corrosion

2. Impact Angle

3. Velocity of Minerals

4. Lubrication

5. Particle Size

6. Particle Shape

7. Temperature

By lining the chute plates with impact and wear resistant liners, many of these wear problems can be overcome.

2. Improving the flow of material across the chute plates.

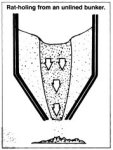

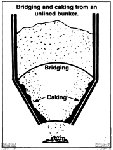

Very often plant managers and system designers are faced with the problem of bunkers, bins, silos and chutes continually hanging up.

These flow obstructions are caused by rat-holing, bridging or build-up of material on bin sides.

Many man hours are lost trying to clear these obstructions and bottlenecks.

By lining the chute plates with low friction liners, many of these problems can be overcome.