| SC |

Description |

Cause |

Effect / Remedy

/ Responsibility |

A/R/N

/C/REP |

Example |

|

1 |

APPEARANCE OF

SODIUM DICHROMATE.

A small amount of sodium dichromate is

generally added to the

quench water bath for passivation. |

Although the recommended

quantity of sodium dichromate is about 0,15 to 0,3%, occasionally when topping up, more is added. This often results in a dark yellow to

brown colour on the galvanized surface. The darker colour will provide enhanced

initial corrosion protection. |

Maintain concentration of

sodium dichromate at about 0,15 to 0,3%. G

|

A |

|

| |

| 2 |

ASH DEPOSITS.

Ash deposits are grey, non-metallic deposits consisting of zinc oxide that

have been deposited no the hot dip galvanized coating.

|

Zinc oxide deposits coo take place when the component is dipped or when it is removed from the both.

|

The coating is normally intact

underneath the ash deposits. Ash must be removed and the coating

thickness verified for conformance to the specification requirements. Remove ash from all liquid conveyance pipes.

G |

A/N

|

|

REP

If

necessary |

| |

| 3 |

BARE SPOTS.

Although excluded from ISO 1461, bare spots of about

5mm (2,2 x 2,2mm), due to small localised flows, ore adequately protected by the sacrificial properties of zinc and will have very little effect on the service life of the coaling. Where necessary, such spots may be repaired using one of the specified repair methods. Gross

uncoated areas ore a cause for rejection. See Coating Repair Procedures.

|

There are several causes of bare spats. These include:

Overdrying. If the time between fluxing and hut dip galvanizing is prolonged or the drying temperature is toe high, the barrier protection provided by the flux may

be lost. This is indicated by a rusty appearance on the

ungalvanized article, which can result in coating discontinuities after hot dip galvanizing.

G

Excess Aluminium. A condition sometimes referred to as black. spats may occur if the aluminium content of a bath becomes too high. No trouble should be experienced if flux concentration is correct and the aluminium content of the both is maintained

below approximately 0,007%. G

Further causes are:

Blowouts; flux deposits; stains and inclusions; mechanical damage; touch marks;

uncoated surfaces caused by - surface contaminants, scale or sand; welds

and weld spatter. See SC No's 6, 16, 19, 30, 33, 34, 35 and 37

|

A/R

|

|

REP

If

necessary |

| |

| 4 |

BLACK STEEL INSPECTION.

Inspection prior to hot dip galvanizing is extremely important.

|

Components should be checked for distortion caused during rolling or fabrication. Check for appropriate vent, fill and drainage holes: removal of weld slag and spatter; venting of overlapping

surfaces; unsuitable joining materials; temporary identification markings; clearance for moving ports and potential distortion due to the

process. |

Insufficient inspection prior to hot dip galvanizing

can be the cause of dispute. G |

A/R |

|

| |

| 5 |

BLASTING DAMAGE.

Sweep blasting, dune correctly, substantially increases paint adhesion and final coating appearance hut done incorrectly can result in coating damage.

|

Incurred nozzle pressure; nozzle angle; sweeping distance; size of abrasive and recycling of

grit. |

A hot dip galvanized coating wi8 be partially or fully destroyed by excessive blasting. Refer to the HDGASA Cede of Practice.

D/B |

R |

|

| |

| 6 |

BLOWOUTS.

Staining and coating defects around unsealed weld areas and vent holes. Similar to stains ceased by

weeping. See SC 28.

|

Pre-treatment chemicals penetrating sealed overlap areas through the required vent holes and escaping during immersion

in the molten zinc. This effect tends to damage the flux coating, causing localised

uncoated areas. |

Pre-heat item prior to immersion in zinc both to dry out overlap area as much as possible.

D/G |

A

|

|

C/REP

If

necessary |

| |

| 7 |

CLOGGED HOLES.

Zinc film clogging or partly bridging holes.

|

Molten zinc has a high surface tension and will not easily drain from holes under 8mm in diameter. |

Make holes as large as possible. Removal of molten zinc over the bath and utilization of vibrators will reduce the likelihood of clogging.

D/G |

A

|

|

C

If

required |

| |

| 8 |

CLOGGED THREADS.

Threaded components or attachments have

threads dogged with zinc.

|

Insufficient centrifuging or poor drainage of threaded attachments on withdrawal from the galvanizing bath. |

The correct centrifuging equipment or post galvanizing thread cleaning by heating, wire brushing or oversize tapping of nuts, will generally remove clogging. If necessary specify delivery of bolts end nuts in nutted up farm.

G |

R |

|

| C/REP |

| |

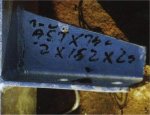

| 9 |

DESIGN

STRUCTURES IN MODULAR LENGTHS AND OPTIMUM WIDTHS TO SUIT AVAILABLE BATH

SIZES.

|

Double dipping can sometimes be used to

hot dip galvanize fabrications that are too long or wide far single immersion. If the fabrication exceeds the bath size, members in the fabrication may require

touching up. |

Touch up and repair can

be avoided, the cost of hut dip galvanizing reduced and the overall quality improved, if the design of the component is restricted to the length, width and depth 0f the galvanizing bath.

D/B |

A |

|

| C/REP |

| |

| 10 |

DISCOLOURING

AFTER HOT DIP GALVANIZING CAUSED BY GRINDING OR OTHER RESIDUES.

|

Materiel stored in contact with rusty steel, or iron filings can cause surface rust staining. |

Once the cause has been removed the stains will gradually disappear.

B |

A

|

|

C

If

possible |

| |

| 11 |

DISTORTION.

Distortion is the unwanted warping that occasionally becomes evident after hut dip galvanizing.

|

The hot dip galvanizing process occurs ala molten zinc temperature of 450 dug C. This is at the lower end of the stress relieving temperature for

treating steel. Thus, any inherent rolling or welding stresses in the fabrication, are

likely to be released. This may result in a dimensional change, i.e. distortion. |

Use

symmetrical designs; Use sections of similar thickness; Stiffen unsupported

thin wall sections; Use preformed members with the correct minimum bend

radii; Use balanced or staggered welding techniques; Make use of temporary braces

on thin walled sections such as troughs, cylinders and angle frames.

Avoid quenching after galvanizing. Components can be straightened after

hot dip galvanizing. D/G |

A/N

|

|

REP

If

possible |

| |

| 12 |

DRAINAGE

SPIKES.

Spikes and teardrops of zinc often appear along the edge of a component after hot dip galvanizing. |

The edge mast

likely to have these spikes is the last to leave the bath on withdrawal.

This applies particularly to complex fabrications. |

Drainage spikes are easily removed at the bath

while still molten but with complex fabrications, the solidified spikes will

be removed by fettling by the galvanizer prior to inspection. G |

A/N

|

|

C/REP

If

possible |

| |

| 13 |

DROSS.

Dross particles are iron/zinc alloy crystals produced when hut dip galvanizing steel. These

precipitate to the bottom of the bath and are removed by the galvanizer.

|

Gross dross deposit from the bottom of the zinc both, trapped in the corner of a fabrication. The dross incorporated in the coating prevents drainage of the zinc in the intermediate area and a build up

occurs. |

Dross consists

of the same iron/zinc alloy as the coating, it will provide the same corrosion protection

as a normal hot dip galvanized coating. G |

R/N

Mechanically remove if

possible, repair or regalvanize |

|

C/REP

If necessary |

| |

| 14 |

DULL GREY OR

MOTTLED COATING APPEARANCE.

Dull grey or mottled coatings can appear as a dark grey circular patter, a

localised dull patch or, may extend over the entire surface of the component.

|

This appearance indicates the presence

of extensive iron/zinc allay phase growth, mused by steels with high reactive levels of Silicon and Phosphorous in

steels. |

Although not as

aesthetically pleasing as a coating with free zinc on the surface, a

dull grey coating provides similar or hotter corrosion protection.

D/S |

A |

|

| |

| 15 |

FLAKING OR

DELAMINATION OF COATING.

No adhesion of zinc to steel surface. Thick, rough coating.

|

High phosphorous content (greater) than 0,03% causes entire

coating to delaminate from the steel. |

Use a steel that has

a phosphorous content of lower than 0,03%. D/S |

R/N |

|

| |

| 16 |

FLUX DEPOSITS,

STAINS AND INCLUSIONS.

Flux deposits or stains from the galvanizing process may adhere to the steel or become included in the

coating. Flux residues are black, brown, grey or

yellowish non-metallic deposits consisting mainly of ammonium chloride. |

Flux deposits or stains may

occur as a result of excessive "dusting" with ammonium chloride on withdrawal from

the molten zinc. Flux inclusions can occur when a surface flux blanket is applied to the zinc surface (wet galvanizing).

Flux blankets are normally only used for specialised processes, e.g. galvanizing of tubes and

fasteners. |

Flux deposits or stains should be removed and the underl~4ng coaling measured to determine whether it conforms to the minimum requirements of the specification.

G |

A

|

|

C/REP

If

necessary |

| |

| 17 |

DISCOLOURATION

OF THE PAINT COATING OVER HOT DIP GALVANIZING AFTER EXPOSURE TO THE

ENVIRONMENT. |

Inadequate repair

of a damaged surface on the hot dip galvanized coating prier to the application of a paint coating. |

Make use of the correct repair materials and application procedures when touching up cut or welded hot dip galvanized components. See Coating Repair Procedures.

B |

R |

|

| REP |

| |

| 18 |

COATING

THICKNESS PROVIDED ON FASTENERS USE TO ASSEMBLE HOT DIP GALVANIZED

STRUCTURES. |

No matter how the zinc coating is applied, the coating life

is proportional to its thickness in a given environment. Often electroplated fasteners with insufficient coating thickness are incorrectly used in external

environments. |

Specify

hot dip galvanized fasteners to ISO 1461, where required. Alternatively overcoat fastener with an approved zinc rich point or epoxy. See Coating Repair Procedures.

D/B |

R

|

|

REP

If

acceptable |

| |

| 19 |

MECHANICAL

DAMAGE.

Mechanical handling or transport damage may occur, particularly with extremely thick coatings, which tend to

be brittle in nature. |

The use of chains, wire ropes, dragging or dropping of the component

onto a hard surface, can cause mechanical damage. This is particularly relevant with thick brittle coatings. |

Warning labels, highlighting a thick

coating and possible damage if manhandled, should be attached by the galvanizer, before the component is transported. The use of nylon lifting slings is recommended.

G/B |

A

|

|

REP

If

necessary |

| |

| 20 |

OXIDE LINES.

Light aluminium oxide film lines on hot dip galvanized surface. |

Due to the shape and/ or drainage conditions of some components, the hoist crane has stopped and started

upon withdrawal of the items from the molten zinc. |

No effect on corrosion resistance. The overall appearance becomes uniform in time.

G |

A |

|

| |

| 21 |

PIMPLES

OR BLISTERS.

Pimples or blisters formed during hot dip galvanizing are usually associated with surface imperfections such as dross inclusions.

|

Dross pimples result from agitation of the dross

layer at the bottom of the bath or from dragging material through the dross layer. They appear as small, hard lumps on an otherwise normal

galvanized surface. Blisters may be formed by hydrogen, which is absorbed daring pickling and diffused at galvanizing temperatures. |

The galvanizer should avoid disturbing the dross layer at the bottom of the

bath by controlling immersion depths and dressing regularly. Since dross pimples represent minor disturbances in coating uniformity, they do not affect

corrosion resistance. G |

A

|

|

C

If

necessary |

| |

| 22 |

REACTIVE AND

NON-REACTIVE STEELS, WELDED TOGETHER.

Variations in coating thicknesses can arise when reactive and non-reactive steels are welded together. Efforts to increase

coating thickness on the less reactive steel may result in an undesirably thick

and brittle coating on the most reactive steel. |

This difference in coating

thickness, is brought about by a combination of a more reactive silicon killed steel, and/or high

phosphorous resulting in a thicker coating and a less reactive aluminium killed steel, resulting in a

coating thickness sometimes below that required in the specifications. Should the

galvanizer be asked to regalvanize in accordance with the specification, the resultant coating thickness on the reactive steel will

be excessively thick, resulting

in a brittle coating more susceptible to damage. |

Select the same steel for fabricating a component. If need

be, accept a concession request by the galvanizer when the thinner coating is possibly

below specification. D/B |

A/N |

|

| |

| 23 |

REMOVAL OF

ZINC COATING BY EXCESSIVE CLEANING.

Unless otherwise agreed, the galvanizer will limit cleaning of the final coating by mechanical means to that required in the specification. |

Excessive

cleaning of the coating, particularly the edges, by mechanical methods,

can result in uncoated areas. |

The affected areas usually only appear

after the component is installed. Care should be exercised by the galvanizer to avoid over cleaning.

G/B |

R

|

|

REP

At the galvanizer or

alternatively at site |

| |

| 24 |

ROLLING

DEFECTS IN STEEL.

These defects maybe broadly classified as surface discontinuities in the steel that

have been elongated during rolling. |

Steel may occasionally include laminations, laps, folds and nonmetallic impurities, which result

in slivers rolled into the metal surface. Defects of this type are sometimes detected before or after pickling, but may only become apparent after

hot dip galvanizing. |

Surface

flaws in the base material maybe removed by local grinding after hot dip galvanizing followed by repair of the affected surface. Minor surface defects will

not adversely influence coating life. S |

A

|

|

REP

If

necessary |

| |

| 25 |

ROUGH COATINGS, CAUSED

BY STEEL SURFACE CONDITIONS. |

Rough surfaces, typical of coatings on corroded steel surfaces, can be hot dip galvanized satisfactorily. The coating will, however, reflect the texture of the substrate. Other causes of rough surfaces include uneven cold working,

over pickling, a high galvanizing temperature and/ or extended immersion in the molten zinc. |

The rougher surface will produce a thicker coating and result

in a longer service life. S |

A |

|

| |

| 26 |

ROUGH HEAVY COATINGS,

CAUSED BY A ROUGH SURFACE AND/OR THE CHEMICAL COMPOSITION OF THE STEEL

"TREE BARK EFFECT" |

Rough, heavy coatings refer to

hot dip galvanized components showing markedly rough surfaces. This can include coatings that have a generally rough surface

and, in some cases, groove type surface configurations, "tree bark

effect" caused by variations in surface steel analysis. |

The thicker coating produced will provide greater corrosion protection.

Except when the coating tends to flake off or delaminate see SC 15.

S |

A/R |

|

| |

| 27 |

ROUGH HEAVY

COATINGS CAUSED BY INSUFFICIENT CENTRIFUGING. |

Efficient centrifuging, will generally remove excess zinc and provide a smooth and attractive exterior. |

Provided the steal/casting surface is reasonably smooth, correctly centrifuged articles will provide an acceptable finish.

G |

R

|

|

C/REP

If

acceptable |

| |

| 28 |

STAINS

CAUSED BY WEEPING. |

The salts from acid or flex

that have penetrated porous welding or between contact surfaces during pickling can weep after

hot dip galvanizing and water quenching, producing a stained

area. |

The stains can be easily removed by means of bristle brushing. Should the component

be destined for a corrosive area, the crevice should be sealed with a sealant after cleaning.

D/B |

A

|

|

C/REP

If

necessary |

| |

| 29 |

TIGHTLY

ADHERENT LUMPS OF ZINC ON THE INSIDE OF HEAVY WALLED STEEL PIPING.

|

Heavy walls and thick flanges used in the manufacture of piping can act

as a heat sink when immersed in molten zinc. This effect considerably lengthens the immersion time. Occasionally the galvanizer will remove the pipes before all the zinc has melted from the inside of the pipe. |

The galvanizer should ensure all zinc hen been removed from the aside of the pipe by longer immersion times.

G |

R

|

|

C/REP

If

acceptable |

| |

| 30 |

TOUCH

MARKS.

The zinc in the galvanizing bath should have free access to all component surfaces or small unmated or damaged areas can result. |

Articles entering the galvanizing baths should not

be in tight contact with each other. Jigging wire should also

be loosely attached to eliminate wire marks. Where a component has been resting on

jigging or dipping equipment, an uncoated area en touch mark could appear. |

Minimise contact between components and

jig connections. (Loosen jigging wire). Small components can be centrifuged.

G |

A

|

|

REP

If

necessary and acceptable |

| |

| 31 |

TYPICAL SPANGLED

HOT DIP GALVANIZED COATING.

A typical hot dip galvanized surface is shown in the example. The surface is silver grey in colour and not necessary but often has a spangled effect (zinc crystals) in a range of sizes. |

Surface appearances may vary according to the chemical composition of the steel. Cooling rate has a direct effect on the surface brightness and spangle size. Easter cooling usually results in a brighter coating with a smaller spangle size. |

Small additions of aluminium to the molten zinc, brightens the coating.

S/G |

A |

|

| |

| 32 |

UNEVEN

DRAINAGE.

Uneven drainage results in an uneven or lumpy area on which zinc build op has occurred. |

This condition can occur over the entire surface Grin isolated areas.

Uneven drainage also includes drips en the ends of ports, runs near halos. The cause is withdrawal speed too high or low galvanizing temperature. |

Although not particularly attractive, this condition dons not adversely affect coating performance.

Protuberances and lumps, which interfere with mating surfaces are unacceptable.

G |

A

|

|

C

If

necessary |

| |

| 33 |

UNCOATED SURFACES

CAUSED BY STEEL SURFACE CONTAMINANTS OR ENTRAPPED AIR. |

Residues, such as oil based paint, grease, oil or

labels on the steel surface or incorrectly positioned vent holes, can result in

localised ungalvanized areas in an otherwise continuous galvanized coating. Defects after galvanizing can very in colour from grey black to brown while no galvanized coating has been formed. |

Ensure all paint or grease is removed prior to hot dip galvanizing. Make usual suitable marking pens for temporary identification. Correctly position adequately sized vent hubs.

B |

A/N/R

|

|

REP

If

necessary |

| |

| 34 |

UNGALVANIZED

SURFACES CAUSED BY SCALE OR SAND. |

Sand on cast iron or scale on

the steel surface is generally caused by the process used to form or roll the product. A localised

ungalvanized area in an otherwise continuous coating can occur if scale or sand from the

moulding or rolling is not removed by acid pickling or abrasive blasting. |

These

ungalvanized areas may occur in a linear pattern on angles, channels or other rolled products. They can also appear on cast

iron products. S/G |

R/N

|

|

REP

If

acceptable |

| |

| 35 |

UNGALVANIZED

AREA IN THE VICINITY OF A WELD. |

A localised

ungalvanized area near a weld can be caused by weld slug deposit, weld porosity or weld undercut. Oxide deposits and residues from welding are resistant to normal pickling adds and mint

be removed before the work is pickled and hot dip galvanized. |

Weld slag deposits should

be removed by the

fabricator by means of abrasive blast cleaning. The deposit can also be removed by proper chipping or wire brushing. Shielded arc welding as opposed to slick welding is preferred for components which are to ho hot dip galvanized.

B |

R/N

|

|

REP

If

necessary |

| |

| 36 |

USE

CONVENTIONAL FIXING METHODS SUCH AS BOLTS AND NUTS, OR REPAIR DAMAGED

COATINGS CAUSED BY WELDING OR NON0-CONVENTIONAL FIXING METHODS. |

Conventional drilling and bolting after hot dip galvanizing is preferred. Should welding or noon-conventional method of fixing

be used, resulting in damage to the

coating, an approved repair method is necessary. |

Coating repair can be done by zinc motel spraying urn zinc rich painter epoxy, providing the product

conforms to the requirements of the specification. (See Coating Repair Procedures).

D/B |

A |

|

| REP |

| |

| 37 |

WELD SPATTER.

Weld spatter is oxidised, normally spherical expelled weld metal, that is fused or not onto the surrounding material during welding. |

Weld spatter is caused by weld pool

explosions when improper welding parameters are used, or if the material is dirty or contaminated. |

Loosely adherent weld spatter should be removed prior to hot dip galvanizing. Although not acceptable in terms of the specification the presence of tightly adherent weld spotter after hot dip galvanizing will not affect the corrosion resistant properties of the coating.

B |

A/N |

|

| |

| 38 |

WET STORAGE

STAIN OR WHITE RUST.

Wet storage stain or white rust as

it is commonly called, is a white voluminous deposit that is occasionally found on the surface of a freshly galvanized coating. |

Wet storage stain (zinc

hydroxide) is formed on freshly galvanized surfaces whirls are in close contact in presence of moisture. Freshly galvanized

coatings react with the environment until such time as a stable zinc carbonate film is formed on the cooling surface. |

Wet storage stain ceases when the cause is

eliminated. If the coating thickness at the affected area is equal to, or greater than the minimum required in the specification, it is

not a cause for rejection, other than for aesthetic reasons. The latter

is subject to discussion with the end user. Customer is to exercise caution during transport and storage.

G/B |

A

|

|

C

If

necessary |

| |

| 39 |

ZINC METAL SPRAYED

REPAIR APPLIED TO INADEQUATELY BLASTED SURFACES OR NOT WIRE BRUSHED

AFTER APPLICATION. |

In order for zinc metal spraying to adhere on application, the damaged galvanized surface mast

be adequately blasted. As it is difficult not to

over spray, excess zinc metal spray loosely adheres to the surrounding coating. |

Prepare surface for repair by adequate blasting. Loosely applied zinc metal sprayed coating at the perimeter of the repair should ho removed by wire brushing If net removed, there is no compromise in the corrosion resistance.

G/B |

A |

|

| C |

| |

| 40 |

ZING

SPLATTER.

Splashes and flakes of loosely adherent zinc, caused by moisture on the steal surface when hot dip galvanizing. |

When hot dip galvanizing an unusually deep fabrication by double dipping, moisture an the surface of the steel contacts with the molten zinc causing splashes of zinc to loosely adhere to the already hot dip galvanized surface. |

The loosely adherent zinc splashes are easily removed. An experienced galvanizer can ensure the coating overlap on double end dipped surface, is not visible.

G |

A |

|

| C |