Steel Protection

By Hot Dip Galvanizing & Duplex Systems

Information courtesy of: HOT DIP GALVANIZERS ASSOCIATION SOUTHERN AFRICA

Hot Dip Galvanizing

The French chemist, Melouin, discovered as long ago as 1741 that zinc was capable of protecting steel from corrosion. However, the method was not used much until another Frenchman, Sorel, introduced pickling in sulphuric acid as a preparatory measure. He subsequently applied for his first patent on hot dip galvanizing on 10th May 1837. The main part of the procedure that Sorel sought to patent is still used today.

In an appendix to his patent application in July 1837, Sorel called the method 'galvanizing'. referring to the galvanic cell that is created if the zinc coating is damaged. The steel in the damaged area becomes a cathode in the cell, and is protected from corrosion. The name has subsequently been adopted by other methods for coating steel with zinc and is sometimes used for electrolytic metal deposition in general. To avoid confusion, hot dipping in zinc should be referred to as hot dip galvanizing.

4.1 THE ADVANTAGES OF HOT DIP GALVANIZING

Lower first cost. Hot dip galvanizing generally has the lowest first cost when compared to other commonly specified comparable protective coatings for steel. The application cost of labour intensive coatings such as painting has risen far more than the cost of factory applied hot dip galvanizing.

Lower maintenance / lower long term cost. Even in cases where the initial cost of hot dip galvanizing is higher than alternative coatings, galvanizing is invariably more cost effective, due to lower maintenance costs during a longer service life. Maintenance is even more costly when structures are located in remote areas. Maintenance programmes also invariably have a negative impact on productivity.

Long life. The life expectancy of hot dip galvanized coatings on structural members is in excess of 50 years in most rural environments, and between 10 to 30 years in most corrosive urban and coastal environments.

Surface preparation. Immersion in acid ensures uniform cleaning of the steel surfaces, in contrast organic coatings must be applied on abrasive blast cleaned surfaces (generally to ISO 8501 - 1 to SA 2) and verified by third party inspection. Additionally, the application of organic coatings is limited in terms of prevailing ambient temperature and relative humidity. This adds to the cost of applying a heavy duty paint system.

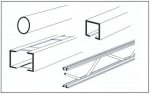

Figure 12. Examples of profiles and structures that are difficult to access hr mechanical cleaning. In hot dip galvanizing, all surfaces receive equally goad coatings.

Figure 13. Micrograph showing the slightly thicker hat dip galvanized coating at corners.

Adhesion. The hot dip galvanized coating is metallurgically bonded to the steel surface.

Environmentally friendly. The coating is not toxic, arid it does not contain volatile substances.

Speed of coating application. A full protective coating can be applied in minutes, a comparable multicoat paint system, may require up to a week. The effective application of a hot dip galvanized coating is not influenced by weather conditions.

Figure 14. Point coatings are usually thinner aver corners and sharp edges. Hot dip galvanized coatings, an the other hand, ore at least as thick or greater at these locations.

Uniform protection. All surfaces of a hot dip galvanized article are protected both internally and externally, including recesses, sharp corners and areas which are inaccessible for the application of other coating methods (figure 12). The coating is at least as thick over sharp corners and edges as on flat surfaces (figures 13 and 14). Thickness, coating adhesion and uniformity are features of the process. No other coating applied to a structure or fabrication can provide similar uniform protection.

Sacrificial protection for damaged areas. A hot dip galvanized coating corrodes preferentially to steel, providing cathodic or sacrificial protection to small areas of steel exposed through damage. Unlike organic coatings, small damaged areas need no touch up while corrosion creep under the coating cannot occur (figures 81 and 82).

Toughness. A hot dip galvanized coating has a unique metallurgical structure, which gives outstanding resistance to mechanical damage during transport, erection and service.

Reliability. Hot dip galvanizing is required to conform to the ISO 1461 specification. The coating thicknesses specified are related to steel thickness. Coating life is reliable and predictable.

Faster erection time. Once steel is hot dip galvanized it can immediately be inspected, transported and erected. When assembly of structures is complete, they are immediately ready for use. No time is lost on-site for surface preparation, painting, drying, curing and final inspection.

Ease of Inspection. Hot dip galvanized coatings are readily assessed visually. Simple non-destructive testing methods are used to determine coating thickness. Inspection of organic coatings is necessary after surface preparation and each stage of coating application thereafter. The hot dip galvanizing process is such that if coatings appear sound and continuous, they are sound and continuous.

Over coating with paint, (duplex protection). if correctly applied a duplex system will provide durable colour, chemical resistance and a synergistically extended service life.

Unsightly graffiti is easily re-moved. Painted graffiti can be easily removed by solvents with no damage to the hot dip galvanized coating. This is not easily achieved with a paint coating.

4.2 THE DISADVANTAGES OF HOT DIP GALVANIZING

Hot dip galvanizing can only be done in a galvanizing plant. Site application is not possible.

The colour of the zinc coating can be changed only by painting.

The dimensions of the component or structure are limited by the size of the zinc bath. Refer to the current copy of Hot Dip Galvanizing Today (Association journal) for available bath sizes or contact the Association.

There is some risk that large flat unsupported sheet surfaces and long, slender beams will warp, due to the relatively high molten zinc temperature. Good design and coned galvanizing procedures will normally prevent distortion.

Figure 15. The principle of hat dip galvanizing.

The welding of zinc-coated steel can demand a somewhat different procedure compared to uncoated steel. The welding of hot dip galvanized steel results in a degree of coating loss through the 1st and 2nd Heat Affected Zones although a portion of the original coating remains intact right up to the edge of the weld. It is necessary to recondition the coating over the weld and surrounding coating. The latest welding techniques do not require zinc to be removed prior to welding.

4.3 THE HOT DIP GALVANIZING PROCESS

General Hot Dip Galvanizing

The metallurgical reaction between steel and molten zinc, which produces a hot dip galvanized coating, can only take place if surfaces are free from contaminants, if steel surfaces are contaminated with marking paint, weld slag and other substances not readily removed by acid, these must first be removed by mechanical means, such as abrasive blasting or grinding. Moulding sand on the surfaces of castings is removed by means of abrasive blasting.

Grease and oil is removed with degreasing chemicals, either caustic or acid based, Rust and millscale are removed from steel surfaces by pickling in diluted hydrochloric or sulphuric acid, After pickling and rinsing, a fluxing agent is applied. The purpose of fluxing is to dissolve surface oxides on both the steel and the molten zinc surfaces thus enabling steel and zinc to make metallic contact with each other. Fluxing can be applied in two different ways, designated wet and dry galvanizing respectively. As far as coating quality is concerned, both methods give equally good results.

In wet galvanizing the surface of the zinc bath is divided into two sections by a weir, The fluxing agent - ammonium chloride, is deposited on the zinc surface in one section of the bath. The steel components, still wet from pickling and rinsing are dipped through the molten flux into the zinc, The components are then moved into the flux-free section of the zinc bath. The flux residue and oxides are skimmed from the surface of the bath, whereupon the components can be lifted up through a pure, smooth zinc surface. Wet galvanizing is largely confined to small components and semi-automatic tube galvanizing.

Dry galvanizing is the preferred method for coating batch galvanized components. After pickling and water rinsing, the components are dipped in a flux solution of ammonium chloride and zinc chloride. In this way a thin layer of flux salts is deposited on the surfaces of components. Before components are dipped into and withdrawn from the bath, the surface of the molten zinc is skimmed to remove zinc oxide and flux residues. After withdrawal from the zinc bath, components are quenched either in a sodium dichromate rinse or plain water. Alternatively, they may be air-cooled. Components are then ready for fettling (if necessary), inspection and dispatch (figure 15).

Centrifuge Hot Dip Galvanizing

Small components such as nails, nuts, bolts, washers and fittings are cleaned as described above and placed in perforated baskets, which are then dipped into the molten zinc. Upon withdrawal from the zinc bath, the basket is placed in a centrifuge. Rotation has the effect of throwing excess zinc off the coated surfaces, leaving the components free from uneven deposits of zinc. The zinc layer on centrifuged articles is somewhat thinner, than that obtained by the general process. Centrifuging is essential for threaded articles, where thread clearance and coating thickness tolerance are critical (figure 15).

Tube Hot Dip Galvanizing

Tubes are hot dip galvanized according to the dry or wet methods - or a combination of both, in continuously operating production lines, immediately after withdrawal from the zinc bath, excess zinc is wiped off external surfaces to provide a smooth and uniform coating. The thickness of the zinc coating can be controlled to some extent by adjusting the air pressure in air wiping equipment. Internal surfaces are cleaned of excess zinc with the aid of steam, which is forced down the bore of the pipe. The tube hot dip galvanizing process is normally only applied to flangeless tubes with a maximum nominal bore of about 200mm. Larger diameters and tubes with flanges are galvanized by way of the general process.

|

EVALUATION OF WET STORAGE STAIN (Refer to Chapters 5 and 1 2) |

||

| Visible effect | Cause | Remedial Action |

| LIGHT WHITE DISCOLOURATION - THIN, WHITE POWDERY DEPOSIT | Caused by moisture trapped between sheets or components during transportation or storage, or by condensation in the absence of adequate ventilation. | None required. The protective properties of zinc are not impaired by the presence of superficial white discolouration. Existing white discolouration deposits will slowly convert to protective basic zinc carbonate. Not suitable for post pointing before removing loosely adhering deposits. |

| HEAVY WHITE DISCOLOURATION - THICK, CRUSTY DEPOSITS | Prolonged adverse storage or inadequate protection during transport, allowing considerable water ingress between closely stacked sheets or components. | Before painting, remove all traces of loosely adhering deposits with stiff bristle brush (not a wire brush). Check residual zinc coating thickness with an electromagnetic thickness gauge. (The electromagnetic thickness gauge is used merely as on indicator of the approximate zinc coating thickness on sheeting. The method cannot be used to fail the coating in terms of thickness.) If the coating thickness is within specification and if the sheet or component is to be used in reasonably dry or freely exposed conditions, no action is required. |

| BLACK STAINING AND WHITE DISCOLOURATION WITH POWDERY DEPOSITS | Usually very early stage of superficial zinc corrosion normally due to the formation of complex surface zinc corrosion product. Black staining does not imply that the zinc coating has been destroyed. | C heck zinc coating thickness using an electromagnetic thickness gouge. (The electromagnetic thickness gouge is used merely as an indicator of the approximate zinc coating thickness on sheeting. The method cannot be used to fail the coating in terms of thickness.) If in doubt contact the HDGASA before painting, due to the complex nature of stains. |

| RED RUST | Corrosion of steel substrate where zinc coating has broken down completely. Should not be confused with superficial staining. | In general, sheet or components showing red rust should be repaired or not used at all. |

Table 5. Evaluation of wet storage stain.