Steel Protection

By Hot Dip Galvanizing & Duplex Systems |

|

Information courtesy of: HOT DIP GALVANIZERS

ASSOCIATION SOUTHERN AFRICA

Corrosion Resistance of Hot Dip Galvanized Coatings

The life of a hot dip galvanized coating is more or less proportional to its

thickness in a given environment. (Table 2).

Hot dip galvanized coatings on steel protect against corrosion in two Ways:

-

Barrier protection is provided by a virtually non-porous film which isolates

the steel substrate from corrosion inducing substances in the surrounding

environment.

-

Cathodic or sacrificial protection is provided at small uncoated surfaces

while corrosion creep under the surrounding coating cannot occur.

The corrosion rate of zinc is low in most environments. This is due to the

natural formation of a stable protective film of zinc conversion products which

develops on the surface of the coating.

12.1 CORROSION RESISTANCE IN THE ATMOSPHERE

When a hot dip galvanized article is withdrawn from the molten zinc, the coating

surface immediately reacts with oxygen and moisture to form combinations of both

zinc oxide and zinc hydroxide. Carbon dioxide in the atmosphere rapidly converts

these surface conversion products into a stable, tightly adhering, basic zinc

carbonate film with very low solubility. This ensures that farther attack of the

underlying zinc is prevented. The initial shiny surface with a metallic lustre

disappears to be replaced by a matt, light grey appearance (figure 74).

|

Figure 74. Exposed surface ala hat dip galvanized coating with outer layer of

pure zinc. The shiny surface disappears to be replaced by grey corrosion products

(sometimes called zinc patina).

|

Figure 75. Map showing atmospheric corrosion rate of mild steel and pure zinc

coatings in South Africa. CSIR Data. Areas C1 to C5 are more or less in terms of

SABS ISO 14713.

|

The atmosphere contains greater or lesser corrosive substances such as

chlorides. In marine environments and sulphur dioxide associated with industrial pollution. Humidity levels, rain patterns and condensation all

influence the degree of corrosion. The different factors can occur in favourable

or unfavourable sequences, one after another, alternately. or in combination

with each other.

It is normal to differentiate between

corrosion rates in:

-

rural environments

-

marine (coastal) environments

-

urban environments

-

industrial environments

(See figure 75 for atmospheric corrosion of zinc).

The atmosphere in cities and industrial areas contains various pollutants. These

are able to attack the stable zinc carbonate film producing more soluble products which can be washed away. Consequently the corrosion rate of galvanized

steel will accelerate. Modern environmental controls are resulting in lower

pollution levels and hot dip galvanizing offers good protection in locations

where previously limited coating life was experienced.

Figure 76. Discoloured surface on lighting column. Coating consists mainly of an iron/zinc alloy that grows out to the surface.

Iron is freed during corrosion,

which leads to rust formation.

It is only surface rust and is of aesthetic significance only. The bracket for

the traffic sign has a coating of pure zinc as an outer layer.

In marine environments the corrosion of zinc is influenced by the salt content

of the air. However, marine air contains small quantities of magnesium salts,

with good passivating influences. Corrosion is therefore not as great as may be

expected. The salt content of the air usually reduces quickly away from the

coast i.e. by 80% over the first 800m from the high water mark.

The colour of corrosion products varies according to the environment in which

they are formed. Marine environments give somewhat whiter corrosion products

compared with rural and urban environments. Corrosion products are usually

darkest in urban environments.

The corrosion of zinc is influenced by many factors. This means that a generally

applicable formula for corrosion rates can not be given.

The ubiquitous nature of hot dip galvanizing means that there is always a

product such as a lamp post or fence near a proposed future site that can be

used to predict future performance.

The Hot Dip Galvanizers Association have frequently been involved in the

assessment of the corrosive conditions prevailing at a particular site, prior to

the selection of the final coating specifications. Knowledge about the corrosion

of zinc, and corrosion rates in different environments, is therefore extensive.

Reddish-Brown Discolouration

Some hot dip galvanized steel can adopt a reddish-brown colour after a period of

exposure. After prolonged exposure, particularly in sulphur-rich atmospheres,

this discolouration can gradually turn black. The discolouration occurs mainly

on coatings of iron/zinc alloy on silicon-killed steels.

The source of discolouration is the corrosion of Fe/Zn alloy to form rust

together with humid air or rain water. Rust has a great ability to colour, and

even small amounts can cause considerable discolouration.

Sometimes when discolouration is severe it is easy to conclude that rust

protection has been greatly reduced, or completely destroyed. However, this is

seldom the case. The iron/zinc alloys give better protection (in some

environments up to 30-40%) to the underlying steel than pure zinc.

If appearance is important, discoloured surfaces can be painted (figures 30, 31

and 76).

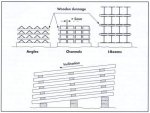

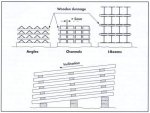

12.2 WET STORAGE STAIN

Sometimes a white, floury and voluminous coating called wet storage stain, or

white rust, appears on galvanized surfaces (figure 77).

The coating forms on materials with newly galvanized, shiny surfaces and

especially in crevices between closely packed sheets, angles and similar

products. A pre condition is that the material is exposed to condensation or rain

water in conditions where the moisture cannot evaporate quickly. Zinc surfaces

that have already received a normal protective layer of corrosion products are

seldomly attacked.

When zinc coatings are exposed to air, zinc oxide and zinc hydroxide are formed.

Under the influence of carbon dioxide in the air these are converted to basic

zinc carbonates. If air access to the zinc surface is restricted, as in narrow

crevices, then the area receives insufficient carbon dioxide to enable the

normal layer of carbonates to form.

The wet storage stain layer is voluminous and porous, and attached only loosely

to the zinc surface. As a result, protection against continued attack does not

exist, Corrosion can therefore continue as long as moisture remains on the

surfaces. When wet storage stain has occurred the object should be stacked to

enable the surfaces to dry quickly. This will stop the attack and, with free

access to air, the normal protective layer will be formed. The wet storage stain

is gradually washed away and the coating acquires an appearance that is normal

for exposed, hot dip galvanized steel.

Since the product of wet storage stain is very bulky (about 500 times that of

the zinc from which it was formed), an attack can appear to be serious. However,

an attack of wet storage stain often has little or no significance on the

service life of the corrosion protection. In the case of very thin coatings

however, e.g. on electroplated objects, a severe attack of wet storage stain can

be of significance.

Wet storage stain is best avoided by preventing newly galvanized surfaces from

coming into contact with rain or condensate during transportation. Materials stored outdoors should be stacked so

that water can run off easily, so that all surfaces are well ventilated (figure

78). Temporary protection against wet-storage stain is obtained through

chromating or phosphating. Painting after galvanizing gives very good

protection.

|

Figure 77. Wet storage stain that has farmed between tightly packed angles.

|

Figure 78. In order to avoid the formation of wet storage stain on newly

galvanized surf aces, profiled steel, beams and structures should be packed at

an angle and turned to prevent the

accumulation of water. Spacers are placed so as to avoid narrow crevices between

the zinc surfaces.

|

|

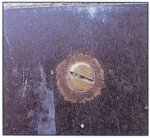

Figure 79. Galvanized bolt in contact with 3CR1 2 plate after 10 cycle SO2 test.

Note the cathodic protection provided by the galvanized bolt head to the

surrounding steel.

|

Wet storage stain which has already formed can be removed completely or

partially by moderate mechanical or chemical treatment. See "Removal of Wet

Storage Stain" page 17.

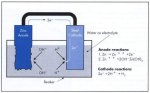

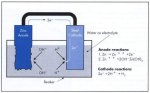

12.3 GALVANIC CORROSION

If two different metals or alloys, completely or partially surrounded by an

electrolyte, are connected, a galvanic cell is created, Which metal becomes

the anode or cathode is determined by their electrode potentials in the

electrolyte in question.

In sea water, which corresponds to the majority of practical conditions, some

metals and alloys take up different positions on the electrochemical scale,

shown in table 24.

If steel is connected to copper or brass the steel becomes the anode in the cell

and corrodes. However, if steel is connected to cadmium, aluminium, zinc or

magnesium, it becomes the cathode and is protected against corrosion, while the

anode metal is consumed (figure 79).

Galvanic corrosion is also called

bimetallic corrosion and is used to protect underwater structures from

corrosion, where it is termed cathodic protection.

Table 24. Electrochemical potential scale in sea water at +25C.

For maximum corrosion resistance under conditions of extreme humidity,

overlapping galvanized surfaces should be insulated from each other by the

application of an inhibitive jointing compound in accordance with SABS 305.

Alternatively a suitable paint may be used. Galvanized surfaces in contact with

other materials may also require insulation.

Galvanized members in contact with aluminium conductors may require the use of

an electrical conducting compound at joint faces, to repel moisture and inhibit corrosion.

|

Figure 80. Galvanic corrosion a! zinc in contact with steel in water.

|

Figure 81. After 20 years of marine exposure, this site cut unrepaired hot dip

galvanized steel grating still offers cathodic protection at the cut ends.

|

|

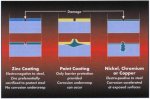

Figure 82. Schematic diagram to illustrate the consequences of damage to

different types of coatings

offering corrosion protection.

|

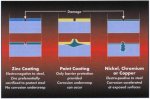

Cathodic Protection Afforded by Zinc Coatings

In hot dip galvanized steel, zinc and steel are in good electrical contact with

each other. If the zinc coating is damaged in the presence of an electrolyte a

galvanic cell is created, The electrolyte could be condensate or rain water.

Sometimes the entire structure can be submerged in liquid. In this cell the zinc

becomes the anode i.e. corrodes, the exposed steel becomes the cathode and is

therefore protected from corrosion (figure 80).

In the initial phase it is possible to see a weak rust formation on the exposed

part of the steel surface where the coating has been damaged, but after a while

whitish-grey areas form which gradually spread over the entire damaged area

(figure 81). The zinc coating corrodes and sparingly soluble zinc alloys descend

to the cathode surface where they protect the steel from continued rust attack.

This is often called self-healing, which is something of a misnomer since the

zinc layer is, of course, not restored.

In case of exposure in water the zinc salts do not always precipitate at the

point of damage since they can be flushed away by movement in the water. The

protective action remains, however, provided that the steel surface is not too

large. The steel is protected by the electrical current generated in the galvanic cell when the zinc corrodes.

Figure 83. Stainless steel fasteners attached to hat dip galvanized plate in

immersed conditions,

note the sacrificial attack of the zinc coating

surrounding uninsulated fasteners compared with the insulated fastener where no

attack of

the surrounding zinc has taken place.

Owing to the cathodic protection generated by the zinc, rust cannot creep in

under the coating at the point of damage in the way that it can creep under

films of paint or coatings of metals more noble than steel (figure 82).

Zinc coatings on steel are unusual, since a fairly large area of damage to the

coating does not cause catastrophic corrosion. The range of cathodic protection

is dependent on the nature of the electrolyte that creates the cell. For

structures in normal atmospheres it is usual to expect protective action over

several millimeters. However, in sea water significantly greater distances can

be expected.

Zinc Coatings in Contact with Non-Ferrous Metals

Aluminium and stainless steel can often be connected directly to galvanized

material in air or fairly dry environments without noticeable corrosion taking

place. However, in water an insulator should always be used to prevent

accelerated corrosion of the zinc (figure 83).

Figure 84. Brass bolt in hot dip galvanized steel on a parking deck.

Copper and copper alloys are more electrically active, and there is often a

release of copper ions which spread over large surfaces and cause noticeable

attack. For this reason, these metals should never be allowed to come into

contact with galvanized steel, and an insulator should always be used (figure

84).

12.4 CORROSION RESISTANCE OF

HOT DIP GALVANIZED

COATINGS IN AQUEOUS

CONDITIONS

General

Zinc carbonate, the protective film formed over a hot dip galvanized coating, is

relatively insoluble in water. However, this stability is restricted to an

acid/alkali pH range of 6 to 12.5. Zinc is amphoteric in nature; that is, it

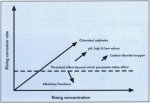

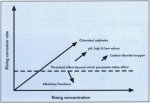

forms soluble salts at low and high pH values. This is clearly shown in figure

85.

Notwithstanding the above, water contains numerous dissolved salts as well as

carbon dioxide and oxygen in solution. Organic matter can be picked up by water

as it passes over vegetation. This can also be a major contributor to corrosion in some instances. The effects of water quality on the corrosion rate are

summarized in figure 86.

In soft waters, zinc corrosion is accelerated. Also, the tolerance for chloride

salts is reduced. A reserve alkalinity level is required to stabilize the zinc

carbonate film, This is generally assumed to be of the order of 50 - 75mg/l (as

CaCO3). In hard waters, high chloride levels (> 2000mg/l) can be tolerated.

Sulphates, nitrates and phosphates are generally considered to be protective

towards hot dip galvanizing. However,

when combined with ammonia compounds (such as with fertilizers) soluble zinc

compounds may be formed and acid conditions can arise causing attack of hot dip

galvanized steel. Organic compounds such as tannins will arrest the corrosion of

hot dip galvanized steel but the settling of solids can create conditions for

crevice corrosion. Similarly, slime build-up should be avoided as microbially

induced corrosion (MIC) can occur, leading to rapid attack.

Flow rates should be maintained at sufficiently high levels to ensure that all

debris is held in suspension rather than allowed to settle. It should be

considered "good practice" to flush systems on a regular basis. This

should be carried out on all fire protection systems although, as the water

entering these systems is generally of good quality, corrosion rates tend to be

low provided that MIC does not occur in all instances, the corrosion performance

of galvanized piping in fire protection systems is far superior to that of bare

steel. Crevice corrosion is likely to occur where sediment becomes dense and

compacted. This may result in the provision of anaerobic sites suitable for the

start of MIC.

Under normal circumstances the amount of dissolved oxygen in a water would be

sufficient to ensure that no deleterious effects occur, However, anaerobic or

septic conditions can affect hot dip galvanized piping adversely as is the case

with other metals. For drinking water purposes some form of chlorination is

generally applied. Therefore, in normal distribution systems anaerobic

conditions giving rise to MIC, should not occur. It is important when testing water lines that clean water be

used and the system drained if it is to be left unused for some time.

Chlorination has no effect upon the protection properties of galvanizing. High

oxygen levels accelerate the corrosion rate of zinc. Similarly, high carbon

dioxide levels tend to produce add conditions, which can accelerate corrosion in

flowing systems.

|

Figure 85. The influence of pH an the corrosion rate of zinc in aerated (CO2

free) solutions.

(Dilute HCl and NaOH at 30C). Note: The curve only applies far continuous

exposure under the specific conditions. Far other conditions it can be used as a

guide. In hard/scale forming waters protective layers are

farmed which greatly alter the curve.

|

Figure 86. Effects of water quality on the corrosion rate

of a hot dip galvanized

coating.

|

Effect of water temperature

Hot dip galvanized piping has been used for hot water supplies with no

deleterious effects in many applications. However, when used above 65C the zinc

is no longer protective to exposed steel. It is therefore recommended that hot

dip galvanized systems not be used above 65C.

The electricity supply commission (Eskom), advise that with proper pipe

insulation, the maximum temperature for hot water cylinders be 60C. For

practical purposes therefore, hot dip galvanized piping is acceptable for use in

both hot and cold water systems.

In domestic systems copper should only be used downstream of hot dip galvanized

piping. This will avoid the possibility of pitting corrosion.

|

No. |

Aggressiveness |

Soil

Condition |

Resistivity

in ohm |

Method of protection |

| 1 |

low |

dry |

> 100 |

Hot dip galvanizing> 200m |

| 2 |

low |

moist |

> 450 |

Hot dip galvanizing > 200m |

| 3 |

moderate |

dry |

< 100 |

Hot dip galvanizing> 200m plus

a rust allowance an the basis

material of 0.5mm on each side. |

| 4 |

moderate |

moist |

150 - 450 |

Same as for 3 |

| 5 |

high |

moist |

50 - 150 |

Hat dip galvanizing > 200m and

rust allowance of 1mm an each side. |

| 6 |

very high

|

moist

(In certain

cases

H2SO4

can form) |

< 50 - 100 |

Same as for 5 but rust allowance

of 1.5mm an each side |

Table 25. Sail aggressiveness at different resistivity levels with hat dip

galvanized coatings.

Effect of sea water

Hot dip galvanized coatings perform relatively well in submerged seawater

conditions which are severely corrosive to most protective systems. Dissolved

salts present in seawater react with zinc to form a protective layer minimizing

corrosive action. The pH of seawater tends to be constant worldwide as a result

of the buffering action of the hydrogen-carbonate salts present. The presence of

pollutants is equally not detrimental provided that levels are within

internationally acceptable norms.

A simple nomogram (table 27) has been produced to allow the specifier to

determine the suitability of hot dip galvanizing for the protection of steel

piping in water. This provides guidance based upon the water quality and general

operating conditions likely to be encountered. More detailed information is

contained in SABS 0374-1: The suitability of hot dip galvanized steel piping for

the transportation of potable water.

12.5 CORROSION RESISTANCE OF

HOT DIP GALVANIZED

COATINGS IN SOIL

CONDITIONS

Soil can contain weathered products, free or bound salts, acids and alkalis,

mixtures of organic substances, oxidizing or reducing fungi, micro-organisms,

etc. Depending on its structure, soil has different degrees of permeability to

air and moisture. Normally, the oxygen content is less than in the air, while

the carbon dioxide content is higher. The corrosion conditions in soil are

therefore very complicated and variations can be great between different

locations, even those in close proximity to each other.

Southern African soils vary from highly corrosive in some regions to moderately corrosive

in others.

One method of determining the corrosivity of a soil is to measure its

resistivity. Recommendations are given in table 25.

If the resistivity of the soil cannot be determined, the rule-of-thumb method

listed in table 26 can give a measure of guidance. Where the exposure of metals

to soil is concerned, it is advisable to seek expert advice from suitably

qualified sources.

See also "Guidelines for Burled Hot Dip Galvanized Conveyance Piping" -

available from the Association.

12.6 HOT DIP GALVANIZED STEEL IN CONTACT WITH BUILDING

MATERIALS

Mortar, Plaster and Wood

Damp mortar and plaster attack zinc. The attack ceases when the material dries

out. Dry or moderately damp wood, both impregnated and unimpregnated, can be

nailed with hot dip galvanized nails to good effect, However, in the case of

nails or threaded unions that are constantly exposed to water an acid-resistant

material is preferred. Other dry building materials, such as mineral wool, do

not attack zinc.

Wood with acidic properties should not come into contact with galvanized steel.

Concrete

Unprotected reinforcement can corrode in certain environments when moisture

penetrates the concrete through cracks and pores. Since rust has a greater

volume than the steel from which it was formed, the covering layer over the

reinforcement can crack and spall (figure 88).

Steel components such as bolts and

edge guards that have been partly grouted in are often poorly protected against

rust. Apart from crack formation and scaling, a problem occurs with unsightly

rust staining on the concrete surfaces below.

|

Soil type |

Aggressiveness |

| Lime, calcareous marl,

moraine, sand marl |

Low |

|

Sand, gravel |

Moderate |

| Clay, peat bag,

humus-rich soils |

High |

Table 26. Corrosivity of different soil types.

| VALUE |

PARAMETER |

UNIT |

RATING |

| CONDITION OF WATER |

A

|

Flowing

Standing

Anaerobic |

|

2

1

-5 |

| CORROSIVITY

INDEX * |

B

|

< 1

≥ 1, < 2

≥ 2, < 5

≥ 5 |

|

0

-1

-2

-4 |

|

TOTAL ALKALINITY |

C

|

< 50

≥ 50, < 200

≥ 200, ≤ 300

> 300 |

ppm as (CaCo3)

|

-1

1

0

-1 |

|

CALCIUM HARDNESS |

D

|

< 50

≥ 50, < 200

≥ 200 |

ppm as (CaCo3)

|

-1

2

3 |

| pH |

E

|

< 5.5

≥ 5.5, < 6.5

≥ 6.5, ≤ 7

> 7 |

|

-6

-4

-1

1 |

|

CALCIUM CARBONATE PRECIPITATION INDEX |

F

|

< -2

≥ -2, < 0

0

> 0, ≤ 6

> 6 |

|

-2

-1

0

1

0 |

| Probability = Sum

(A to F) |

Result

Greater than 1

1 to -1

-3 to -5 |

Performance

Satisfactory (+25 years)

Fair

Unsatisfactory |

* Corrosivity index (B) can be

calculated by -

(C1 x 0,03) + (SO4 x 0,04) |

Table 27. Probability of performance.

This kind of damage can be avoided if the reinforcing steel is hot dip

galvanized (figure 87). Hot dip galvanized reinforcing steel or mesh can

therefore be used in grouted facade sections. One of the advantages of this is

that there is no risk of rust runs discolouring the facade.

Figure 87. Flat dip galvanized reinforcing bars prior to casting concrete,

marine conditions.

According to the Building Research Establishment in the UK, the average adhesion

for smooth reinforcement steel in concrete is as follows:

|

hot dip galvanized steel |

3.3-3.6 MPa |

|

black steel |

1.3-4.8 MPa |

The large range for black steel stems from different degrees of rust and

compositions of oxide scale.

According to work done in Finland, the stress for 0.1 mm of slip in

reinforcement bars in concrete is approximately as follows:

|

black steel |

150 MPa |

|

hot dip galvanized steel |

160 MPa |

| hot dip galvanized and

chromated steel |

190 MPa |

When concrete is cast its pH value is around 13. At this high pH, fresh zinc is

attacked and hydrogen is produced, which could give rise to poor adhesion.

However, the attack ceases as soon as the concrete has hardened and any residual

pores are not harmful.

In order to avoid fresh zinc surfaces coming into direct contact with wet

concrete it is advisable to allow the galvanized steel to age for several weeks.

The cover layer of basic carbonates which then appears will minimize both attack

and the production of gas, and will also promote adhesion. Another common way of

preventing attack from fresh concrete is to chromate the galvanized steel. A

further alternative is to add about 40 ppm (by mass) of chromates, to the water

when concrete is mixed.

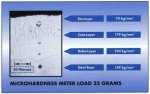

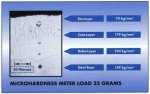

12.7 ABRASION RESISTANCE OF HOT

DIP GALVANIZED COATINGS

Pure zinc is a soft metal, even though it is harder than most organic coating

materials. The iron/zinc alloys produced in hot dip galvanized coatings are,

however, very hard. In fact, they are harder than ordinary structural steel

(figure 89).

The alloys are therefore more resistant to abrasion than pure zinc and

experiments have shown that the alloy layer has a resistance to abrasion 4-5

times that of pure zinc.

Hot dip galvanized articles are often used when the surface is to be subjected

to abrasion. Examples of this include stairs, floor hatches, hand railings, grid

flooring and walkways (figure 5).

12.8 HOT DIP GALVANIZED

COATINGS EXPOSED TO

ELEVATED TEMPERATURES

Conventional zinc coatings can be exposed continuously to temperatures up to

about 200C and non-continuously to temperatures of up to 350C.

At sustained temperatures in excess of 200C a diffusion reaction begins inside

the coating and causes the outer layer to split-off from the underlying

iron/zinc layer. However, the iron/zinc layer has a very good resistance to

corrosion and can, depending on its thickness, protect the steel from rust for a

very long time.

Aluminium-alloyed zinc layers on thin sheet can resist even higher temperatures.

Aluzinc and galvalume for instance, can withstand sustained temperatures up to 315C.

|

Figure 88. Spoiling of the concrete layer an reinforcing steel in a concrete

bridge balustrade.

|

Figure 89. Microsection of a hat dip galvanized coating showing variations in

hardness through the coating.

|