1. Open grid Flooring

Rectangular open grid flooring consists of a series of transverse bars forming a rectangular open grid pattern. The bars form the two main components namely:

- The bearer bar - which carries the applied loads.

- The transverse bar - which separates and supports the bearer bars to form a fixed pattern

|

|

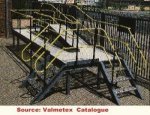

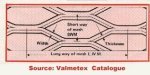

2. Expanded Metal Flooring

Expanded metal flooring consists of a solid sheet of metal that is slit and expanded in a cold drawing operation into a lattice of diamond meshes in which the strands are set at a sharp angle, imparting strength and rigidity to the sheet. The size of the diamond mesh as well as the thickness of the strand have a direct bearing on the strength of the sheet. |

|

Punched Metal Flooring

Punched metal flooring consists of a solid sheet of metal that is slit and punched in in modular panels. The punched areas form a serrated tooth-like pattern which have excellent non-slip properties. The modular panels may be bolted together to form walkways etc.

|

|

Pressed Metal Flooring

Pressed metal flooring consists of a solid sheet of steel which is pressed complete with a slightly protrudingchequered diamond mesh pattern or a protruding nodule pattern. These patterns enhance the non-slip properties of thid particular type of flooring. |

|