Hydrodynamic Couplings in Belt Conveyor Drives for Bulk Materials

H. Holler, Germany

1. Introduction

The design of reliable belt conveyors, particularly for steady operating conditions, is governed by numerous standards and regulations. The design engineer has to pay special attention to the starting and braking sequences with a view to the service life and the capital cost of the belt. These operating conditions can be influenced positively by judicious use of hydrodynamic couplings in belt conveyor drives.

2. Hydrodynamic Power Transmission

In the conveying and materials handling industry, hydrodynamic couplings are generally installed between motor and gear unit. As a result of their operating characteristics, the interaction between driving motor and belt conveyor can be influenced as follows:

Separation of motor start-up and belt conveyor start-up

Delayed and/or controlled build-up of belt tension

Torque limitation (steplessly adjustable)

Switch-on delay and load sharing for multi-motor drives

Damping of torsional vibrations

Creep speed (depending on coupling design)

Conveyor at standstill while the motor is still running (depending on coupling design).

Hydrodynamic couplings based on the Fottinger principle are described in VDI standard no. 2153. An elementary coupling consists of two bladed wheels (centrifugal pump and turbine). These blades are surrounded by a shell and form a working space in which the operating fluid circulates (Fig. 1).

Fig 1 : Physical Laws Mechanical power is transmitted wear free as the circulating fluid flows continuously between pump and turbine wheel. Torque is created by a change of kinetic energy of the fluid when passing from the pump to the turbine wheel.

Commensurate with physical laws, hydrodynamic couplings (turbo couplings) are classified as fluid machines. These machines are characterised by torque being transmitted proportionally to the square of the input speed. If portrayed graphically, this is designated as primary behaviour or slip parabola [2].

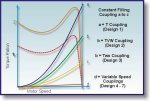

The operating behaviour (secondary behaviour) can be represented by the characteristic relationship of the performance figure µ = f(v) (characteristic curve) (Fig. 2). Usually, the characteristics of a turbo coupling are described as a function of the torque depending on the speed ratio v = nT/nP of various fillings (secondary performance chart). Depending on coupling type and filling volume, the magnitude and shape of relevant characteristic curves may vary considerably.

Fig 2 : Typical characteristics of two coupling types. In order to achieve a mass flow which transmits power, a difference in speed between pump and turbine is required even during nominal operation. This difference is mainly quoted as slip s = 1 = v

For start-up and overload couplings, the characteristic curve occurring during continuous operation should be as steep as possible, in order to keep the slip during nominal operation at a minimum.

In the high slip range up to the breakaway point MA the curve should run horizontally to achieve torque limitation. Absolute levels of torque can be transmitted by varying the fluid level.

For variable-speed and fill-controlled couplings, the curve for any filling should fail continuously while the speed is increasing. In this way, controlled start-up phases with narrow torque limitation are possible. If the interception between coupling curve and load curve is clear-cut, it is possible to set stable operating points below the nominal speed, e.g. for inspection of the unloaded conveyor.

Developing a curve which is perfect for the application solely in accordance with hydraulic laws is still very difficult. Coupling curves are therefore mainly determined during tests.

The primary and secondary characteristics of a coupling are best illustrated in a three-dimensional diagram (Fig. 3). When looking at the system, such a graph is useful if the torque being built up during motor run-up is sufficiently high to break away the conveyor.

Fig. 3 shows all relevant hydrodynamic correlations. As a result of the reciprocal action between primary and secondary function, coupling curves can be achieved that take into account criteria such as time, speed, slip and filling volume.

Fig 3 : Basic coupling design 3. Coupling Types and Designs

Hydrodynamic couplings are manufactured in a great variety of sizes and designs for the entire performance and speed range required by the materials handling industry. Some of the features of hydrodynamic couplings which are relevant for specific applications are part of their design or type. Apart from the steady-state characteristics of a conveyor, its start-up and retardation behaviour must also be taken into consideration when a coupling is selected.

With reference to VDI standards, the couplings suitable for belt conveyors can be classified as shown in Fig. 4. The classification depicts two basic types with seven individual designs that would normally be used for materials handling.

Fig 4 : Types and designs of hydrodynamic couplings for belt conveyors. The constant-fill coupling is the most popular type used for bulk materials handling (Fig. 5), due to its uncomplicated design, minimum maintenance and very competitive cost.

This coupling type is filled with operating fluid prior to commissioning, and there is no external oil supply.

For designs 2 and 3 (Fig. 4), the operating fluid for the coupling is distributed differently, particularly for operating conditions other than continuous operation (e.g. starting and stopping).

This coupling type is mainly chosen to enable a no-load start of the motor, torque limitation and to influence the torsional vibration behaviour. Their basic characteristic curve corresponds to the one shown in Fig. 2 for start-up and overload couplings.

Variable-speed and fill-controlled couplings are used on belt conveyors with special requirements relating to the build-up of tensile force, torque limitation and operating behaviour.

Variable-speed couplings which allow altering the fluid level in the working chamber are available in two basic designs. These couplings are equipped with an additional external fluid circuit which can be used for varying the fluid level as well as cooling.

For design 4 (Fig. 6), the fluid level is set by means of a radially movable scoop tube. The design may be varied by different arrangements of scoop tube, oil tank and oil supply. In principle, the performance chart refers to the design shown for variable-speed and fill-controlled couplings.

Fig 6 : Variable-speed coupling with scoop tube SVN (Design 4) With designs 5, 6 and 7, the fluid level is determined by matching the supply flow rate with the discharge rate of fluid at the spray nozzles. Pilot or control valves are used as actuators in the supply flow. Design 5 (Fig. 7) distinguishes itself by its compact design, good control behaviour and lower losses compared to designs 6 and 7.

Fig 7 : Variable-speed coupling with discharge pump DTPK (Design 5) Selection Criteria

4.1 No-load Start of Motor

For belt conveyor drives, asynchronous motors are now widely used. The advantages of these motor types, i.e. minimum maintenance and simple direct online (DOL) starting, are not ideal for belt conveyor start-ups. Also, the starting behaviour, limited thermal load capacity and high current are unattractive.

With DOL, the motor builds up its break-away torque in milliseconds and generates its design-inherent torque during start-up. This torque vs. speed curve is a characteristic feature of the individual motor and its characteristic does not depend on the load torque.

Dependent on its type and design, the hydrodynamic coupling can aid the asynchronous motor in several ways.

The load on the motor during start-up resulting from load torque and the mass to be accelerated is solely determined by the coupling; the belt conveyor is virtually separated from the motor. The coupling torque is built up from zero with the square of the motor speed.

For identical nominal operating conditions, the amount of start-up load can be selected from a wide range.

Depending on their design, constant-fill fluid couplings can build up a considerable amount of torque during motor start-up (Characteristic curves a to c). Empty variable-speed couplings, on the other hand, just generate a slip torque which can be regarded as insignificant (Characteristic curve d).

Even the constant-fill coupling of design 1 without delay chamber already provides noticeably softer motor start in the peak current range. It allows torque to build-up in seconds rather than milliseconds and its operating fluid provides additional thermal storage capacity on for start-up. The graph in Fig. 8 also shows how this type has developed in recent years from T to TVV and TVVS couplings with delay chamber and annular chamber.

The application of variable-speed and fill-controlled couplings of designs 4 to 7 eliminates the disadvantageous features of asynchronous motors almost completely.

Fig 8 : Build-up of coupling torque in relation to motor speed with output (turbine wheel) at standstill 4.2 Belt Stress During Start-Up

In large conveyor systems, the belt is in most cases the most expensive component and therefore determines the investment cost and the economy of the entire plant. Plant engineers and operators therefore ask for the development of an ever more improved design for the optimum conveyor belt selection.

As a consequence it is vital that drive systems meet these criteria. Non-steady operating conditions such as starting and stopping with varying loads make high demands on drive systems.

The drive system is expected to provide a smooth build-up of torque (initial belt pull), low torque limitation and adaptation of the starting torque to the load condition. All variable-speed couplings with suitable actuators allow that torque build-up and close adaptation to load conditions can take place within the narrowest of limits.

Depending on their design, constant-fill couplings fulfil the expectations to varying degrees (Fig. 9). Based upon investigations on the dynamic stress in belt conveyor systems, the torque build-up time TA is introduced to compare and evaluate the belt pull. The belt can always be assumed to experience quasi-static stress, if the torque build-up time TA is five times larger than the shock wave travelling speed TU on the return belt. The relevant synergies are illustrated in Fig. 9, where c represents the shock wave travelling velocity, dependent on the belt design and the free belt length L.

The three constant-fill coupling designs have the following features:

Fig 9 : Belt stress during start up with various constant-fill couplings Design 1 (T Coupling)

Suitable for shorter belt conveyors with a possible torque limitation of up to 1.8 times the nominal torque at good nominal slip. The torque is not adapted to the load condition of the conveyor. Applications are usually found in combination with gear motors.Design 2 (TV and TVV Coupling)

Suitable for medium-size belt conveyors with a possible torque limitation of up to 1.6 times the nominal torque for TV and 1.4 times the nominal torque for TW couplings. Due to the system, the starting curve adapts itself by a limited amount to the load condition. Standard designs are available in combination with motor and gear unit.Design 3 (TVVS Coupling)

As a result of its smooth build-up of torque, this type is suitable also for longer belt conveyors with starting times up to 50 s. Torque limitations of up to 1.4 times the nominal torque are possible at good nominal slip. Excellent adaptation of the starting torque to the load condition of the conveyor. For starts without load, the starting torques are below the nominal torque, hence protecting the belt. This coupling design is the result of long-term co-operation of Voith with belt conveyor manufacturers and operators. The long experience in manufacturing turbo couplings is illustrated on the table for constant-fill couplings (Fig. 10).

Fig 10 : Constant-fill coupling series As a result of the fluid volume being separated during start-up (V, W, S), centrifugally operated valves (F) control the emptying of the delay chamber (Y) as a function of slip, to produce an optimum starting characteristic. This is achieved with standard components common to all couplings used for crushers, chain conveyors, etc.

4.3 Selection Criteria Depending on Application

Apart from the selection criteria given by motor and belt, other application inherent factors have to be borne in mind.

Heat increases in proportion to the slip which is the operating principle of a hydrodynamic coupling. During steady operation or starting this 'slip' heat can be dissipated via the surface (constant-fill with standard components common to couplings) or via an external cooling circuit with heat exchanger (variable-speed couplings).

Therefore, the number of starts per operating period and the installation and environmental conditions should be taken into consideration, as they may impair the dissipation of heat.

With multi-motor drives, load sharing of the motors occurs automatically due to the coupling slip, which can be further enhanced by changing the oil fill. Unequal loads might be the result of differing belt tension at the drive drums.

In addition, differences may occur even with new conveyors as a consequence of the drum diameter tolerances and the rated motor slip (according to VOE 0530 +/-20%). These effects can be reinforced by wear and replacement of drive components. The slip adaptation is carried out by changing the fluid level while the conveyor is at standstill, or, with variable-speed couplings, by controlling the fluid level.

Turbo couplings can influence the stopping of the belt conveyor directly (with variable-speed couplings; by interrupting the power flow as a result of draining) or less so indirectly (with constant-fill couplings; by separating the separation the rotating masses). Due to their operating principle, turbo couplings are suitable both for special operating conditions such as creep speed (variable-speed couplings) and regenerative braking. These operating conditions have to be discussed in more detail with the coupling manufacturer.

5. Examples of Application

In the materials handling industry, an individual belt conveyor is often just a link in a close chain of materials handling machinery. In synergy with other machines and equipment, the conveyor should guarantee a continuous flow of materials.

The start-up control and operation monitoring system of individual conveyors and their drive systems should be suitable for integration into a central control system, in order to ensure that the entire plant can be operated automatically.

Arduous starting conditions can be caused by weak electrical systems and/or the build-up of dirt and dust, which can be endemic in mines, etc.

For such complex installations, variable-speed with adjustable scoop tube or variable-fill couplings are the preferred choice. Drives with variable speed couplings allow the motors to be started in sequence while the coupling is drained, which minimises the strain on the electrical system. The belt conveyor can only be started after receiving green light from the general operation monitoring system (voltage, speed, lubrication pressure, etc.). With integrated systems it is particularly important that the starting sequences and starting times of the individual conveyors are adapted with each other. Therefore, start-up times should be adjustable, independent of the load condition (Fig 11.)

Fig 11 : Starting a belt conveyor with a variable-speed coupling After the release signal from the monitoring system, the conveyor is started by a micro-processor-controlled start-up system. The control system is designed as a multi-stage control cascade with different parameters. The torque build-up time is used as the main control variable until the conveyor has broken away, while constant acceleration is used as a control variable after conveyor break-away. Subordinate control circuits can be used in order to monitor whether the torque limits, the operating fluid temperature and, with multi-motor system, the load sharing are correct.

Specific start up problems can be solved either by using a drive unit complete with start-up controller and an interface that is compatible with the central control system (Fig 12), or a compact coupling unit (Fig 13) that can be integrated into the customers own system.

Fig 12 : Drive unit with scoop tube - variable speed turbo coupling

Fig 13 : 560 kW drive unit for underground application. 750 DTPK fill-controlled coupling with water as operating medium In practice, companies often use different coupling types for various belt conveyors, in order to achieve optimum operating conditions. Compared to a variable-speed coupling, the constant fill coupling type TWS (Fig 13) with its simpler design offers sufficient performance characteristics for belt conveyor applications.

This coupling has been developed specifically for the super soft start of belt conveyors. In addition to its internal delay chamber it also features an external annular chamber.

The following paragraph describes the distribution of the operating fluid and its effect on the operation of the coupling for the three operating conditions "standstill", "100% slip" and "normal operation".

when the conveyor is at standstill, the operating fluid is distributed to the three chambers (delay chamber, working chamber and annular chamber). During motor start-up and 100% slip the operating fluid level in the delay chamber remains almost constant, while the external annular chamber is filled with fluid from the working chamber as a result of centrifugal effect during the initial motor revolutions.

The remaining fluid in the working chamber builds up a very low torque from standstill. The working chamber is then filled (time-dependent via internal nozzles) with the fluid from the delay chamber. In this way it is possible to achieve a low starting torque during motor run-up with ensuing smooth build-up of torque and low slip in normal operation (see Fig. 9).

The smooth torque build-up and the adaptation to existing load conditions have been proven on the test stand while the customer was present (Fig. 15).

A belt conveyor was simulated by a fixed fly-wheel mass and a controlled mechanical multiple-disc brake; a squirrel-cage motor rated at 200 kW/1500 rpm was used as the driver. The torque MK transmitted by the coupling was measured versus time. In each case, the start of the measurements was initiated by motor speed. In all load conditions, from 'empty conveyor' (1) to 'overloaded conveyor' (3) the coupling builds up the torque required for that condition.

In condition (1) the belt conveyor was started already during the motor run-up phase, in condition (2) start-up took place approximately 7 seconds after motor run-up, while it occurred after approximately 22 seconds when the conveyor was overloaded, but still with excellent torque limitation.

Measurements and data collected at Hanover University are based upon a well coordinated conveyor system which runs steeply uphill, with two drums and a three-motor head drive.

The motors are started consecutively. After the motor run-up, the torque which is proportional to the power consumption, is only slightly in excess of that necessary to run the conveyor at constant speed (permanent power).

This good torque limitation is only possible in very well balanced systems, as the characteristic curve for constant-fill couplings will always show slight modulations as a result of its operating principle.

Fig 14 : TVVS constant-fill coupling operation

Fig 15 : Characteristic torque curve of a type 487 TVVS coupling. Torque adaptation capability was proven on the test stand.

Fig 16 : Steep belt conveyor system with type 562 TVV constant-fill coupling. 6. Concluding Remarks

The application of hydrodynamic couplings on belt conveyors and the operating principles of these couplings are governed by the criteria on which individual coupling types or designs are selected. The aforementioned examples can only be regarded as an extract of the numerous applications for hydrodynamic couplings on belt conveyors for bulk material conveying.

References

VDI regulation 2153: Hydrodynamic Power Transmission; April 1994.

VDI Regulation 3602: Belt conveyors for bulk materials; part 2, draft 1996.

FUNKE, H.: Hydrodynamic couplings in conveyor systems; Lecture at Esslingen Technische Akademie, April 1984.

HOLLER, H.: Control of drive units by means of hydrodynamic couplings; VDI- Z, Special, Oil Hydraulics and Pneumatics 1/1989.

Measurements carried out at Hanover University on behalf of Voith Turbo, Crailsheim.