| Beginners Guide |

|

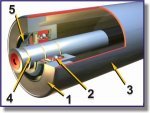

Anatomy of a troughed conveyor belt idler

The design and manufacture of idler roll assemblies, although not a complicated science is nonetheless a specialised field. Many entrepreneurs have entered this field assuming it to be 'basic' and have failed.

The internal components of idler rolls are essentially the same although variations occur from one manufacturer to another. In addition, the quality of idlers also varies depending on the quality of the individual components and of the manufacturing process.

A typical idler can be seen below together with an indication of the individual components :-

Description of components :-

|

1 |

Plastic Grease Plug--Coloured for grease type and year of manufacture. |

|

2 |

Weather Seal - Non-rubbing, water and fire resistant. |

|

3 & 5 |

Outer Seal Components - Multi-labyrinth non-rubbing close rubbing (Press fit seals) |

|

4 & 6 |

Inner Seal Components. |

|

7 & 11 |

Circlip - Locates bearing on shaft (one end only), spring steel hardened and tempered. |

|

8 |

Bearing - Deep groove single row precision ball or spherical roller, single row C3 & C4 clearance. |

|

9 & 10 |

Rear Seal Assembly--Combination pressed metal/plastic, non-rubbing seal. |

|

12 |

Identification Slot. |

|

13 |

Shaft Ground shaft accurately located circlip grooves. |

|

14 |

Shell and end, deep drawn steel pressing and concentric bearing housing bored with .001 inch tolerance. |

|

15 |

Corner Radius - Generous radius on corner of roller, essential to protect belt. |

|

16 |

Rigid Shell- Small runout. |

|

17 |

Breather hole. |

In addition to the idler roll itself, an idler set is supported in position by an idler bracket or base frame. These bases and brackets locate the individual idler rolls relative to each other and provide the necessary 'trough' angle.

Examples of standard idler support frames and brackets are provided, courtesy of Melco, which can be viewed by clicking on the applicable thumbnails :-