Beginners Guide

Design Considerations

The following points are provided to assist the designer in selecting the correct locking element for a particular application.

The items listed are considered important to the selection process.

a) Design data

To commence with the selection of a locking element, details about the particular application are essential.

The following information should be obtained :-

The particular application where the locking element is to be used e.g. on a pulley or on a flanged coupling.

The type of hub or coupling to be used including basic dimensions.

The maximum torque which must be transmitted into the shaft by a flanged coupling via the locking element.

The maximum torque which the locking element must transmit to the pulley hub.

The diameter of the shaft and hub or coupling, etc.

The maximum axial forces which the locking elements should withstand.

The extent of bending in the shaft.

The specification for the shaft and hub materials used, in order to ensure that deformation does not occur.

Details of any physical limitations or constraints which may be imposed on the design or selection of the type of locking elements used.

Details of preferred suppliers products or brand names.

Determine whether standardisation of equipment will affect the selection of components.

b) Mechanical properties of locking elements

The mechanical properties of the locking elements must be considered as this establishes whether or not a particular component can satisfy the performance requirements.

The specific details of different locking elements must be obtained from the suppliers.

Examples of the mechanical properties of RINGFEDER-Type ______ locking elements is provided below :-

Table showing mechanical properties of locking elements

|

B |

T |

F |

Ps |

PH |

M |

B |

T |

F |

Ps |

PH |

M |

|

20 |

0,27 |

27 |

210 |

90 |

14 |

140 |

20 |

298 |

165 |

125 |

125 |

|

22 |

0,30 |

27 |

195 |

90 |

14 |

150 |

24 |

324 |

170 |

125 |

125 |

|

24 |

0,36 |

30 |

195 |

90 |

14 |

160 |

28 |

350 |

170 |

130 |

125 |

|

25 |

0,38 |

30 |

190 |

95 |

14 |

170 |

32 |

386 |

160 |

120 |

190 |

|

28 |

0,47 |

33 |

185 |

95 |

14 |

180 |

37 |

420 |

165 |

125 |

190 |

|

30 |

0,50 |

33 |

175 |

95 |

14 |

190 |

46 |

490 |

150 |

115 |

190 |

|

35 |

0,70 |

40 |

180 |

105 |

14 |

200 |

52 |

525 |

150 |

115 |

190 |

|

40 |

0,92 |

46 |

180 |

110 |

14 |

220 |

68 |

620 |

150 |

115 |

295 |

|

45 |

1,61 |

72 |

210 |

125 |

35 |

240 |

85 |

715 |

160 |

125 |

295 |

|

50 |

1,77 |

71 |

190 |

115 |

35 |

260 |

104 |

800 |

165 |

130 |

295 |

|

55 |

2,27 |

83 |

200 |

130 |

35 |

280 |

128 |

915 |

145 |

115 |

405 |

|

60 |

2,47 |

83 |

180 |

120 |

35 |

300 |

153 |

1020 |

150 |

120 |

405 |

|

65 |

3,04 |

93 |

190 |

130 |

35 |

320 |

210 |

1310 |

150 |

120 |

580 |

|

70 |

4,60 |

132 |

210 |

130 |

70 |

340 |

224 |

1310 |

145 |

115 |

580 |

|

75 |

4,90 |

131 |

195 |

125 |

70 |

360 |

294 |

1630 |

145 |

115 |

780 |

|

80 |

5,20 |

131 |

180 |

120 |

70 |

380 |

308 |

1620 |

135 |

110 |

780 |

|

85 |

6,30 |

148 |

195 |

130 |

70 |

400 |

322 |

1610 |

130 |

105 |

780 |

|

90 |

6,60 |

147 |

180 |

125 |

70 |

420 |

374 |

1780 |

135 |

110 |

780 |

|

95 |

7,90 |

167 |

195 |

135 |

70 |

440 |

455 |

2060 |

130 |

105 |

1000 |

|

100 |

9,60 |

192 |

195 |

135 |

125 |

460 |

470 |

2040 |

125 |

100 |

1000 |

|

110 |

10,50 |

191 |

180 |

125 |

125 |

480 |

515 |

2160 |

125 |

100 |

1000 |

|

120 |

13,10 |

218 |

185 |

135 |

125 |

500 |

560 |

2240 |

125 |

100 |

1000 |

|

130 |

17,60 |

272 |

165 |

115 |

125 |

|

|

|

|

|

|

Where :-

'T' = Transmissible Torque

'F' = Axial Force Absorbed

'Ps' = Pressure Between Locking Assembly And Shaft

'PH' = Pressure Between Locking Assembly And Hub

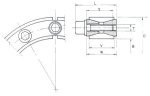

'M' = Torque Per Locking Screw (Applied By Torque Wrench)c) Dimensions of locking elements

The physical dimensions of the various locking elements should be considered.

Dimensions for the following locking element are provided in the table below :-

Table showing dimensions of ___ Type locking elements

(Refer to diagram above)

|

BASIC DIMENSIONS |

LOCKING SCREW |

MASS kg. |

||||||

|

B |

D |

W |

V |

L |

T |

S |

No. |

|

|

20 |

47 |

20 |

17 |

27,5 |

M6 |

18 |

8 |

0,24 |

|

22 |

47 |

20 |

17 |

27,5 |

M6 |

18 |

8 |

0,23 |

|

24 |

50 |

20 |

17 |

27,5 |

M6 |

18 |

9 |

0,26 |

|

25 |

50 |

20 |

17 |

27,5 |

M6 |

18 |

9 |

0,25 |

|

28 |

55 |

20 |

17 |

27,5 |

M6 |

18 |

10 |

0,3 |

|

30 |

55 |

20 |

17 |

27,5 |

M6 |

18 |

10 |

0,29 |

|

35 |

60 |

20 |

17 |

27,5 |

M6 |

18 |

12 |

0,32 |

|

40 |

65 |

20 |

17 |

27,5 |

M6 |

18 |

14 |

0,34 |

|

45 |

75 |

24 |

20 |

33,5 |

M8 |

22 |

12 |

0,57 |

|

50 |

80 |

24 |

20 |

33,5 |

M8 |

22 |

12 |

0,6 |

|

55 |

85 |

24 |

20 |

33,5 |

M8 |

22 |

14 |

0,63 |

|

60 |

90 |

24 |

20 |

33,5 |

M8 |

22 |

14 |

0,69 |

|

65 |

95 |

24 |

20 |

33,5 |

M8 |

22 |

16 |

0,73 |

|

70 |

110 |

28 |

24 |

39,5 |

M10 |

25 |

14 |

1,26 |

|

75 |

115 |

28 |

24 |

39,5 |

M10 |

25 |

14 |

1,33 |

|

80 |

120 |

28 |

24 |

39,5 |

M10 |

25 |

14 |

1,4 |

|

85 |

125 |

28 |

24 |

39,5 |

M10 |

25 |

16 |

1,49 |

|

90 |

130 |

28 |

24 |

39,5 |

M10 |

25 |

16 |

1,53 |

|

95 |

135 |

28 |

24 |

39,5 |

M10 |

25 |

18 |

1,62 |

|

100 |

145 |

33 |

26 |

47,0 |

M12 |

30 |

14 |

2,01 |

|

110 |

155 |

33 |

26 |

47,0 |

M12 |

30 |

14 |

2,15 |

|

120 |

165 |

33 |

26 |

47,0 |

M12 |

30 |

16 |

2,35 |

|

130 |

180 |

38 |

34 |

52 |

M12 |

35 |

20 |

3,51 |

|

140 |

190 |

38 |

34 |

52 |

M12 |

35 |

22 |

3,85 |

|

150 |

200 |

38 |

34 |

52 |

M12 |

35 |

24 |

4,07 |

|

160 |

210 |

38 |

34 |

52 |

M12 |

35 |

26 |

4,3 |

|

170 |

225 |

44 |

38 |

60 |

M14 |

40 |

22 |

5,78 |

|

180 |

235 |

44 |

38 |

60 |

M14 |

40 |

24 |

6,05 |

|

290 |

250 |

52 |

46 |

68 |

M14 |

45 |

28 |

8,25 |

|

200 |

260 |

52 |

46 |

68 |

M14 |

45 |

30 |

8,65 |

|

220 |

285 |

56 |

50 |

74 |

M16 |

50 |

26 |

11,22 |

|

240 |

305 |

56 |

50 |

74 |

M16 |

50 |

30 |

12,2 |

|

260 |

325 |

56 |

50 |

74 |

M16 |

50 |

34 |

13,2 |

|

280 |

355 |

66 |

60 |

86,5 |

M18 |

60 |

32 |

19,2 |

|

300 |

375 |

66 |

60 |

86,5 |

M18 |

60 |

36 |

20,5 |

|

320 |

405 |

78 |

72 |

100,5 |

M20 |

70 |

36 |

29,6 |

|

340 |

425 |

78 |

72 |

100,5 |

M20 |

70 |

36 |

31,1 |

|

360 |

455 |

90 |

84 |

116 |

M22 |

80 |

36 |

42,2 |

|

380 |

475 |

90 |

84 |

116 |

M22 |

80 |

36 |

44 |

|

400 |

495 |

90 |

84 |

116 |

M22 |

80 |

36 |

46 |

|

420 |

515 |

90 |

84 |

116 |

M22 |

80 |

40 |

50 |

|

440 |

545 |

102 |

96 |

130 |

M24 |

90 |

40 |

64,6 |

|

460 |

565 |

102 |

96 |

130 |

M24 |

90 |

40 |

67,4 |

|

480 |

585 |

102 |

96 |

130 |

M24 |

90 |

42 |

71 |

|

500 |

605 |

102 |

96 |

130 |

M24 |

90 |

44 |

72,6 |