| Locking Elements |

|

Machining Tolerances

Machining Tolerances - Shaft and Hub Bore Dimensions

The tapered surfaces of the locking assembly form an angle of approximately 28 degrees. The inner and outer rings are split and consequently, only minor clamping movements and forces are required for radial deformation.

For this reason, relatively large deviations from nominal sizes can be bridged without significant torque losses.

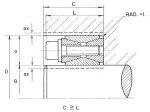

To prevent excessive distortion of the double tapered thrust rings and to ensure correct functioning of the locking assemblies however, it is essential that the assembly is symmetrically located in the annular ring 'a' as shown in the diagram above.

When nominal shaft and hub bore sizes are used, this condition automatically exists. Deviations resulting from machining tolerances specified above are easily absorbed by the locking assembly without regard to symmetrical location.

Where sizes deviate from nominal sizes within the limits given in the last column of the table below, it is essential that a smaller diameter shaft be matched with an appropriately larger hub bore or vice versa, thereby maintaining the locking assembly symmetry within the annular ring 'a'.

For example, if the selected shaft diameter 'B' is 0,152 mm undersize, then the hub bore 'D' must be 0,152 mm oversize, i.e. dimensions 'ax' above must be equal within the deviation limits given.

When the shaft and hub bore dimensions have been determined, the following machining tolerances should be applied.

Required surface finish for shaft and hub bore is NIO i.e. 12,5m.