| Sole Plates |

|

2. Sole Plate Details

a) Anatomy of a sole plate

For the purpose of clarity the following diagram indicates a typical sole plate installed for a conveyor pulley bearing support assembly.

Click on the thumbnail for a larger image.

PIC

The conveyor pulley shaft (1) is supported in a bearing (2) by means of a plummer block (3). The plummer block is then bolted to the support structure (4) however, the base of the plummer block is seated onto a sole plate (5).

The sole plate comprises a machined steel plate (5a) which is tack welded to the support structure (4), jacking bolts (5b) and lock nuts (5c).

The jacking bolts are used to align the pulley horizontally before the plummer block securing bolts are finally tightened.

Should shims be required for packing under one of the plummer blocks, these are inserted between the sole plate and plummer block for finer pulley alignment.

b) Mounting details

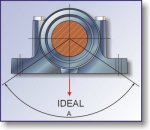

Sole plates should be mounted such that the direction of the force imposed by the shaft, pulley and belt tension should fall within the limits of the angle 'A' indicated on the adjacent sketch.

This angle is equivalent to the angle subtended at the centre of the shaft by the intersection of the centre lines of the holding down bolt holes and the underside of the plummer block base.

Ideally, the direction of the force should be vertically downwards through the centre of the shaft when related to the sketch above.

Plummer block mountings must be arranged accordingly.

c) Installation

Generally speaking, sole plates are either tack welded or fully welded to the pulley support structure.

Slotted holes are to be machined into the support steelwork to coincide with the adjustment slots in the sole plates.

d) Standard sole plate data

The following information is sourced from SKF for sole plates and represents three standard sole plates for a variety of plummer blocks.

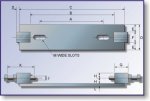

i. _______-type sole plate

Diagram of sole plate

Notes:-

- To be supplied with 2 hex set screws, 'J' diameter x 'k' mm long and 2 plain nuts.

- 6mm full weld required all around jacking blocks.

- Soleplates to be fully welded to supporting steelwork.

- All dimensions in the table below are in millimeters.

Table indicating sole plate dimensions

| BelRef. | Dimensions | Mass kg. | |||||||||||||

| A | B | C | D | E | F | G | H | J | K | L | M | N | P | ||

| 001 | 130 | 235 | 305 | 50 | 10 | 30 | 40 | 15 | M12 | 115 | 8 | 15 | M12 | 40 | 2,5 |

| 002 | 150 | 255 | 325 | 55 | 12,5 | 30 | 40 | 15 | M12 | 115 | 8 | 15 | M12 | 40 | 2,7 |

| 003 | 170 | 275 | 345 | 65 | 17,5 | 30 | 40 | 15 | M12 | 115 | 8 | 15 | M12 | 40 | 3,5 |

| 004 | 210 | 330 | 400 | 75 | 17,5 | 40 | 40 | 20 | M16 | 115 | 10 | 19 | M16 | 45 | 5,0 |

| 005 | 230 | 355 | 425 | 85 | 22,5 | 40 | 40 | 20 | M16 | 115 | 10 | 19 | M16 | 45 | 5,8 |

| 006 | 260 | 395 | 465 | 100 | 30 | 40 | 40 | 20 | M16 | 115 | 10 | 24 | M20 | 45 | 7,1 |

| 007 | 290 | 420 | 510 | 110 | 30 | 50 | 50 | 25 | M16 | 125 | 10 | 24 | M20 | 45 | 9,2 |

| 008 | 320 | 460 | 550 | 120 | 35 | 50 | 50 | 25 | M20 | 125 | 10 | 28 | M26 | 50 | 10,8 |

| 009 | 350 | 490 | 580 | 130 | 40 | 50 | 50 | 25 | M20 | 125 | 12 | 28 | M26 | 50 | 11,9 |

| 010 | 380 | 525 | 615 | 140 | 45 | 50 | 50 | 25 | M20 | 140 | 12 | 28 | M26 | 50 | 13,2 |

| 011 | 420 | 590 | 680 | 160 | 55 | 50 | 50 | 25 | M20 | 140 | 12 | 35 | M30 | 60 | 15,9 |

| 012 | 450 | 620 | 710 | 170 | 60 | 50 | 50 | 25 | M20 | 140 | 12 | 35 | M30 | 60 | 17,4 |

| 013 | 470 | 640 | 730 | 170 | 60 | 50 | 50 | 25 | M20 | 140 | 12 | 35 | M30 | 60 | 17,9 |

Table indicating standard plummer block series for sole plates

| Soleplate | SKF. Plummer Block Series | |||||||

| Bel Ref. No. | SNA.6 | SN.6 | SNA.5 | SN.5 | SNA.3 | SN.3 | SNA.2 | SN.2 |

| 001 | 505 | 505 | 205 | 205 | ||||

| 002 | 605 | 605 | 506 | 506 | 305 | 206 | 206 | |

| 002 | 606 | 606 | 507 | 507 | 306 | 207 | 207 | |

| 003 | 607 | 607 | 508 | 508 | 307 | 208 | 208 | |

| 003 | 608 | 608 | 509 | 509 | 308 | 308 | 209 | 209 |

| 003 | 510 | 510 | 210 | 210 | ||||

| 004 | 609 | 609 | 511 | 511 | 309 | 309 | 211 | 211 |

| 004 | 610 | 610 | 512 | 512 | 310 | 310 | 212 | 212 |

| 005 | 611 | 611 | 513 | 513 | 311 | 311 | 213 | 213 |

| 005 | 214 | |||||||

| 005 | 612 | 612 | 515 | 515 | 312 | 312 | 215 | 215 |

| 006 | 613 | 613 | 516 | 516 | 313 | 313 | 216 | 216 |

| 006 | 517 | 517 | 314 | 314 | 217 | 217 | ||

| 007 | 615 | 615 | 518 | 518 | 315 | 315 | 218 | 218 |

| 007 | 616 | 616 | 519 | 316 | 316 | |||

| 008 | 617 | 617 | 520 | 520 | 317 | 317 | 220 | 220 |

| 009 | 619 | 522 | 522 | 222 | 222 | |||

| 009 | 620 | 524 | 524 | 224 | 224 | |||

| 010 | 526 | 526 | 226 | 226 | ||||

| 011 | 528 | 528 | 228 | 228 | ||||

| 012 | 530 | 530 | 230 | 230 | ||||

| 013 | 532 | 532 | 232 | 232 | ||||

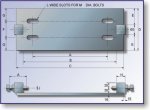

ii. _______-type sole plate

Diagram of sole plate

Notes:-

- To be supplied with 2 hex set screws, 'J' diameter x 'k' mm long and 2 plain nuts.

- 6mm full weld required all around jacking blocks.

- Soleplates to be tack-welded to supporting steelwork.

- All dimensions in the table below are in millimeters.

Table indicating sole plate dimensions

| Bel Ref. | Sd. Brg. Hsg | Shaft Dia. | Dimensions | Mass kg. | ||||||||||||

| A | B | C | D | E | F | G | H | J | K | L | M | N | ||||

| 101 | 3134 | 150 | 430 | 600 | 680 | 200 | 70 | 100 | 50 | 50 | M24 | 150 | 35 | M24 | 60 | 20,6 |

| 102 | 3136 | 160 | 450 | 620 | 700 | 200 | 70 | 110 | 45 | 50 | M24 | 150 | 35 | M24 | 60 | 21,1 |

| 103 | 3138 | 170 | 480 | 650 | 730 | 230 | 85 | 120 | 55 | 50 | M24 | 150 | 35 | M24 | 60 | 24,6 |

| 104 | 3140 | 180 | 510 | 700 | 780 | 250 | 95 | 130 | 60 | 50 | M24 | 150 | 35 | M30 | 60 | 27,8 |

| 105 | 3144 | 200 | 540 | 730 | 810 | 250 | 95 | 140 | 55 | 50 | M24 | 150 | 35 | M30 | 60 | 28,8 |

| 106 | 3148 | 220 | 600 | 790 | 920 | 280 | 110 | 150 | 65 | 75 | M30 | 180 | 35 | M30 | 60 | 37,2 |

| 107 | 3152 | 240 | 650 | 870 | 1000 | 300 | 120 | 160 | 70 | 75 | M30 | 180 | 42 | M36 | 70 | 42,3 |

| 108 | 3156 | 260 | 670 | 890 | 1020 | 300 | 120 | 160 | 70 | 75 | M30 | 180 | 42 | M36 | 70 | 43,0 |

| 109 | 3160 | 280 | 710 | 930 | 1060 | 330 | 135 | 190 | 70 | 75 | M30 | 180 | 42 | M36 | 70 | 48,6 |

| 110 | 3164 | 300 | 750 | 980 | 1110 | 350 | 145 | 200 | 75 | 75 | M30 | 180 | 42 | M36 | 70 | 53,4 |

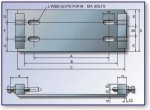

iii. _______-type sole plate

Diagram of sole plate

Notes:-

- To be supplied with 4 hex set screws, 'J' diameter x 'k' mm long and 2 plain nuts.

- 6mm full weld required all around jacking blocks.

- Soleplates to be tack-welded to supporting steelwork.

- All dimensions in the table below are in millimeters.

Table indicating sole plate dimensions

| Bel Ref. | Sd. Brg. Hsg | Shaft Dia. | Dimensions | Mass kg. | ||||||||||||

| A | B | C | D | E | F | G | H | J | K | L | M | N | ||||

| 101 | 3134 | 150 | 430 | 600 | 680 | 200 | 70 | 100 | 50 | 50 | M24 | 150 | 35 | M24 | 60 | 20,6 |

| 102 | 3136 | 160 | 450 | 620 | 700 | 200 | 70 | 110 | 45 | 50 | M24 | 150 | 35 | M24 | 60 | 21,1 |

| 103 | 3138 | 170 | 480 | 650 | 730 | 230 | 85 | 120 | 55 | 50 | M24 | 150 | 35 | M24 | 60 | 24,6 |

| 104 | 3140 | 180 | 510 | 700 | 780 | 250 | 95 | 130 | 60 | 50 | M24 | 150 | 35 | M30 | 60 | 27,8 |

| 105 | 3144 | 200 | 540 | 730 | 810 | 250 | 95 | 140 | 55 | 50 | M24 | 150 | 35 | M30 | 60 | 28,8 |

| 106 | 3148 | 220 | 600 | 790 | 920 | 280 | 110 | 150 | 65 | 75 | M30 | 180 | 35 | M30 | 60 | 37,2 |

| 107 | 3152 | 240 | 650 | 870 | 1000 | 300 | 120 | 160 | 70 | 75 | M30 | 180 | 42 | M36 | 70 | 42,3 |

| 108 | 3156 | 260 | 670 | 890 | 1020 | 300 | 120 | 160 | 70 | 75 | M30 | 180 | 42 | M36 | 70 | 43,0 |

| 109 | 3160 | 280 | 710 | 930 | 1060 | 330 | 135 | 190 | 70 | 75 | M30 | 180 | 42 | M36 | 70 | 48,6 |

| 110 | 3164 | 300 | 750 | 980 | 1110 | 350 | 145 | 200 | 75 | 75 | M30 | 180 | 42 | M36 | 70 | 53,4 |