|

|

|

Beginners Guide

3. Design Considerations for Pulleys

The procedure for selecting pulleys for a conveyor for any given application involves the evaluation of a number of factors pertinent to the installation.

This section of the Handbook outlines the main factors affecting pulley design however, for a more comprehensive design procedure, consult the pulley design section.

Consideration should be given to the following :-

a) Application / Environment

The specific application for which the pulley is required should be understood.

A conveyor may require a self-cleaning bend pulley for a tripper or a gravity take-up pulley. Short conveyors are sometimes designed with crowned pulleys rather than flat pulleys, to assist with training of the belt while long overland conveyor drive pulleys must be lagged and the drive is a shaft-mounted unit.

Having listed the different pulleys on the project, the designer should consider the environment in which the pulleys are to operate. Pontoon-mounted drive pulleys found on a dusty ash dump for example, may require special bearings and seals compared to a pulley on a conveyor in a fertilizer plant where the environment is extremely corrosive and may require a stainless steel pulley.

The choice of whether or not pulley lagging is required is often dependant of whether the pulley and belt is to operate in a wet, moist or dry condition. This affects the friction between the belt and pulley which in turn affects the decision to include lagging or not.

b) Conveyor design

For each conveyor the engineer is required to undertake a complete design. The outputs from this design specify the belt width, the drive selection, the conveyor profile, the location and arrangement of the pulleys and take-up, the tensions in the belting and

the belt selection, etc.

As far as the design and selection of pulleys is concerned, the following information is generally required from the conveyor design and application :-

| Belt width: |

The belt width will dictate the minimum face width of the pulley. The following table indicates standard belt and pulley face widths. |

| Belt Width (mm) | Pulley Face Width (mm) |

| 450 | 550 |

| 500 | 600 |

| 600 | 700 |

| 750 | 900 |

| 900 | 1050 |

| 1050 | 1200 |

| 1200 | 1350 |

| 1350 | 1500 |

| 1500 | 1700 |

| 1650 | 1850 |

| 1800 | 2000 |

| 2100 | 2300 |

| 2400 | 2600 |

Belt tensions: Irrespective of where the pulley is located in a conveyor system, the pulley will have to be designed with the belt tensions in mind.

Belt tensions will affect the shell design as well as the shaft design, bearing selection and orientation of the tensions relative to the support structure for the bearing mounts.

Belt tension calculations should include the tensions based on a dynamic analysis of the conveyor under load. This issue becomes a significant consideration when longer conveyors are designed.

For examples of the forces applied to pulleys, click on the following thumbnails.

Conveyor duty: The selection of bearings includes a calculation to determine the life expectancy of the bearings. The duty of the conveyor i.e. hours operated per year and load conveyed will affect the pulley bearing design and life.

In addition to this, the design of the pulley shaft, shell, locking element, etc. requires an understanding of the duty of the conveyor and hence pulley.

Belt selection: The type and class of conveyor belting to be used on a conveyor has a direct bearing on the diameter of a pulley.

The minimum pulley diameters recommended by belt manufacturers should be observed in order to prevent over-stressing of the belt.

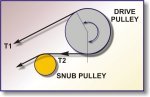

Angle of Wrap: The design will specify the angle of wrap of the belt around the drive pulley(s). This angle of wrap is required to ensure that the full torque can be introduced to the belt through the drive pulley.

The angle of wrap affects the load seen by the pulley and the resultant force which the shaft support bearings and plummer blocks must be designed for and the orientation of the bearing housings.

c) Standardisation

The client may have specified a preferred pulley type and design and the components to be used i.e. pulley shell dimensions, locking elements, etc. may be specified in order to standardise on the spares holding requirements at the site, and for interchangeability.

Such information is essential and may affect the design of the new conveyor and its components. In the case of pulleys, the drive may require two 55 kW drives and pulleys to be installed rather than a single 110 kW drive through one pulley.

The shaft detail may be affected by the type of drive unit and the mounting detail for example, a hollow shaft-mounted reducer versus a flexible low speed coupling.

d) Specifications

The clients' standard specifications may call for specific design procedures and selection criteria to be applied to pulley design.

Factors of safety or the allowable deflection in the shaft which the client wishes to prescribe, must be taken into consideration when designing a pulley.

e) Layout

The particular layout of the conveyor may affect the design of a pulley assembly.

In a case where access is extremely restricted, the discharge chute at the head pulley may require the pulley bearings to be closer together than the standard width so that the chute can be narrower.

Another example could be the need to install two drive units onto one pulley, rather than a single drive unit mounted onto one pulley. This may be necessary to standardise on a particular drive size.

f) Pulley design

The design of the pulley and its components must take into consideration a number of factors listed below :-

Dimensions: Standard pulley dimensions should be observed wherever possible, in the interests of standardisation in the industry.

The following chart provides a guideline for the standard pulley dimensions.

Belt width Face width Chute plates I/S Bearing centres Clearances for wide centres

See legend belowWide Narrow W F A B C D E G 450 550 650 1000 760 225 50 50 500 600 700 1050 810 225 50 50 600 700 800 1150 1020 225 50 50 750 900 1000 1350 1170 225 75 50 900 1050 1150 1550 1370 250 75 50 1050 1200 1300 1700 1520 250 75 50 1200 1350 1450 1850 1680 250 75 50 1350 1500 1600 2050 1830 275 75 50 1500 1700 1850 2300 1980 300 100 75 1650 1850 2000 2450 2130 300 100 75 1800 2000 2150 2600 2280 300 100 75 2100 2300 2450 2900 2580 300 100 75 2400 2600 2750 3200 2880 300 100 75 Legend:-

D = Pulley face to centre-line bearing housing.

E = Pulley face to belt edge.

G = Pulley face to inside chute plate.

Accessories: Locking elements, bearings and plummer blocks are off-the-shelf components manufactured in standard sizes and for certain limitations.

The design of pulleys and shafts must take this into consideration.

Click the following to view some tables of standard equipment for pulleys.

PIC x 3

Drive friction: The transmission of torque from the drive unit to the belting through the drive pulley is a further factor which affects the design of the pulley.

The following table provides the recommended friction factor for pulleys under different operating conditions :-

PIC

Materials: The materials of manufacture may affect the design of the shaft, hubs, shells and end plates.

If an application requires a pulley to manufactured in stainless steel for example, this may have a bearing on the shell thickness, fabrication technique, reinforcing, etc.

The detailed design of pulleys and their component selection should thus be undertaken by experienced engineers and equipment suppliers.