Plummer Blocks

Lubrication

The following is an extract from the SKF catalogue, edited for this Handbook.

Pulley plummer blocks and bearings do not require frequent re-lubrication under most operating conditions however, where the environment is harsh, provision can be made for frequent greasing or oiling. This is outlined below.

If frequent re-lubrication is required, housings fitted with 'V'-ring seals should be selected (suffix TA). Excess grease can escape from the housing past the lip of the 'V'-ring and the risk of hot running because of over-lubrication is reduced.

The efficiency of re-lubrication can be much improved by mounting an extra perforated 'V'-ring inboard of the 'V'-ring seal washer at the side where grease is applied so that grease can only leave the housing at the opposite side.

Housings of series SNA 5 and SNA 6 with 'V'-ring seals are therefore available complete with an extra 'V'-ring, grease nipple and splash plate.

It should be noted that where possible, grease should be supplied to housings with these additional features (suffix TAV, e.g. SNA51OTAV) on the side away from the lock nut.

Housings with 'V'-ring seals can be adapted for oil lubrication; see adjacent illustration.

It is necessary to drill entry and exit holes for the oil and to supplement the seals. The holes should be drilled one at each side of the bearing so that oil must pass through it.

Good sealing is obtained if an extra 'V'-ring is mounted at each side of the housing in an inboard position with its lip against the steel washer. The extra V'-rings should be of the perforated type.

At peripheral speeds in excess of 7 m/s it may be necessary to locate the 'V'-ring axially.

If a wide bearing is used, the steel washer should be turned, for reasons of space, so that its rubber lip faces inwards.SD plummer blocks can be re-lubricated. The plug in the lubrication housing base can be replaced by a grease nipple.

The grease penetrates the bearing via the lubrication groove and three holes in the outer ring (VJ33 feature).

The housings are also suitable for oil lubrication. Bosses indicate where holes can be drilled in the base and cap for entry and exit of the oil and also to take an oil level gauge and a drain plug.

Where circulating oil lubrication is used, the supply may be connected to the lubrication duct in the housing base.

SN plummer blocks of series SN 5 and SN 6 are coupled with felt seals only. End covers for housings to be mounted at shaft ends are available; further details are available on request.

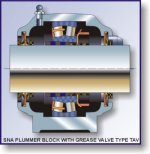

For arrangements requiring frequent re-lubrication, housings with grease valves are available. The housing dimensions are in accordance with ISO/R 113. The bearing seating is machined to tolerance H7.

SD plummer blocks of series SD 31 TS are designed to take large spherical roller bearings or Series 231 C. The housings are fitted with labyrinth rings. These have a clearance fit but a rubber 'O'-ring inserted between the ring and the shaft ensures that the ring rotates with the shaft and also permits slight axial displacements caused by thermal changes in shaft length.

Housings for shaft ends are supplied with an end cover instead of one of the labyrinth rings; further details are available on request. The bearing seating is machine to tolerance H8.