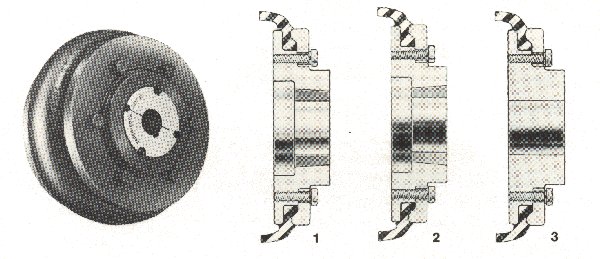

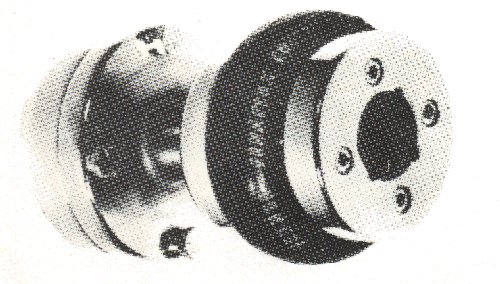

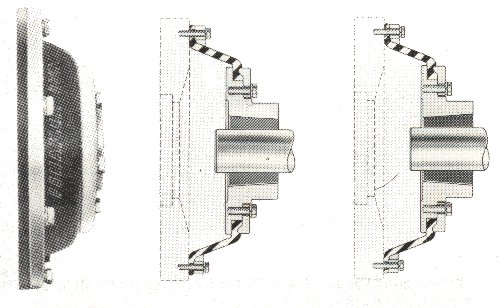

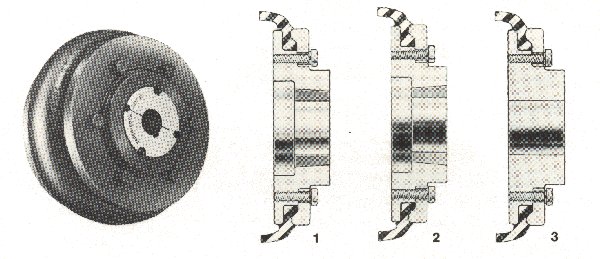

To enable designers and engineers to gain maximum advantage from this versatile range of couplings it is presented as individual flanges.

Fenaflex couplings embody all the desirable features of an ideal flexible coupling, including Taper-Lock fixing. They accommodate parallel mis-alignment up to 6 mm, angular misalignment up to 4 end float up to 8 mm.

The excellent shock-absorbing properties of the rubber component reduce vibration and torsional oscillations.

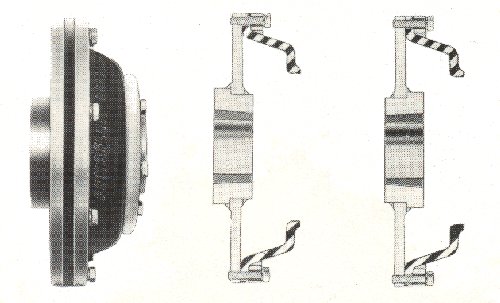

Fenaflex tyres and elements are available in natural rubber compounds for use in ambient temperatures between minus 50 C and plus 50 C.

Neoprene rubber compounds are used for temperatures of minus 15 C to plus 70 C or under adverse operating conditions - e.g. oil or grease contamination.

As contact between the metal flanges is eliminated Fenaflex couplings provide a certain degree of electrical isolation. However, for applications where fire-resistance and anti-static properties are required, neoprene (FRAS) tyres or elements should be used.