| Dust Control at Conveyor Transfer Points: Containment, Suppression and Collection |

|

L.J. Goldbeck and A.D. Marti, U.S.A.

Section 1: - Introduction

Controlling fugitive matehal at conveyor transfer points has been a problem from the time the conveyor belt was invented. Cleaning up matehal lost from conveyors has cost the solids handling industries millions of dollars a year, year after year. Shoveling the same piles of material lost from conveyors, day after day, continues to drain maintenance budgets. The value of components damaged or prematurely worn by fugitive dust exceeds millions of dollars. And the costs for avoidable safety hazards, unwanted community attention, and preventable regulatory citations continue to escalate.

For any industry, unnecessary and repetitive costs such as clean-up can no longer be tolerated. In today's marketplace, a much different approach to controlling dust must be adopted. Sending workers out to shovel the same piles of material time and again does not solve the problem. Correcting the source of the lost material is the only long-term answer. No longer will a "band-aid" approach be acceptable; it is time for a solution.

Section 2: - Three Dust Control Technologies

2.1 - Competing or Cooperating?

In the past, three different approaches - containment, suppression, and collection - have been used to control dust arising at conveyor load zones.

- Dust Containment consists of those mechanical systems employed to keep material inside the transfer point with the main material body.

- Dust Suppression systems increase the mass of suspended dust particles, allowing them to fall from the air stream.

- Dust Collection is the mechanical capture and return of airborne material after it becomes airborne from the main material body.

Previously, these three approaches have always been seen as separate entities. They were offered by separate organizations competing in the marketplace. The three technologies vied for their individual "piece of the rock" at the expense of the other technologies (and often at the expense of overall success). There have been considerable amounts of "I'm better" selling, as well as "finger pointing" at the other systems when problems arose. Each system claimed its own technology was the best, providing the most effective, most cost-efficient, most maintenance-free solution to fugitive material.

2.2 - Changes in Problem Emphasis

But expectations are changing. In "the old days", plants were worried about keeping most of the lumps on the belt. More recently, the concern was fines escaping from the loading zone. Concerns have now extended to the fugitive dust carried from the belt by air movement, and there is growth in government regulations mandating improvements in air quality. There is an overall rise in awareness in industry (and in the general public) of the problems caused by airborne dust and other fugitive materials. As a result, a much more in-depth solution must be provided. No longer can just one of the "big three" be expected to do the entire job of dust control.

To succeed, the three systems should be seen not as competitors, but rather as interrelated components working together to solve fugitive material problems. All three systems should be evaluated, separately and together to determine the most effective and efficient way to solve dust problems, and then integrated into a system that forms a combined defense to act in concert to prevent the loss of fugitive material and the creation of airborne dust.

Section 3: - Characteristics of Each Dust Control System

In any system the first step is material containment. The requirements for suppression and collection are determined by the individual characteristics of process, equipment and material.

3.1 - Dust Containment

Containment is the mechanical control and confinement of material on the conveyor or load zone. It is the base of the pyramid, the most fundamental step in fugitive material control. By incorporating effective systems to contain material at the transfer point, the engineer can avoid overloading the dust suppression and dust collection systems and greatly improve their chances for success. Each conveyor and each loading zone present a different challenge due to the unique characteristics of the material and components at that given conveyor and load zone.

The sources of fugitive material include belt carryback, conveyor side spillage, tail area spillage, and exit area dust creation. Each source must be identified and corrected as part of a total fugitive material containment system.

3.1.1 - Carryback

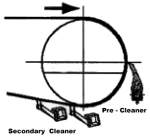

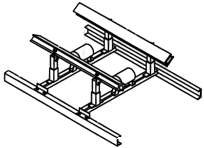

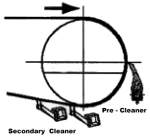

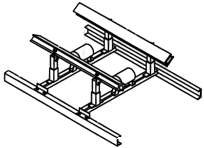

For the control of material adhering to the belt past the discharge point the state-of-the-art is the use of multiple belt cleaner systems (Fig. 1). These consist of a precleaner on the face of the head pulley to remove the majority of material and one or more secondary cleaners to perform final precision cleaning. The secondary cleaner(s) are installed at the point where the belt leaves the head pulley or further along the conveyor return. For maximum cleaning washboxes which first wet the belt and then remove the water and fines can be specified.

Fig. 1: Multiple cleaner systems consist of a precleaner on the face of the head pulley, and one or more secondary cleaners

Cleaners must be designed for continued effective cleaning performance with minimal wear or damage to the belt. To avoid these risks cleaners should incorporate multiple blades applied with low blade-to-belt pressure. Cleaners should allow easy installation and easy maintenance.

3.1.2 - Skirt Spillage

Loading zone spillage is best controlled by a three-part program consisting of:

- Proper belt support to minimize belt sag

- Wear liners inside the chute to protect the sealing system

- Multiple-layer edge seals to contain any escaping fines.

Belt Support

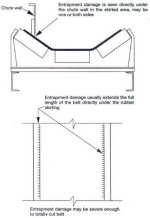

Insufficient belt support allows material to become entrapped at the belt sag between the idlers (Fig. 2). The resulting pinch point creates material entrapment that accelerates the wear of the skirt seal, which leads to the release of fugitive material.

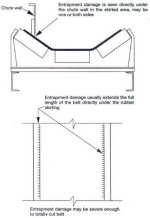

In addition, material entrapment often turns into dramatic belt damage near belt edges (Fig. 3). To eliminate this expensive damage requires proper belt support.

Fig. 2: Belt sag allows spillage and risks material entraprnent and belt damage. In addition, a creates pinch points that can trap material and damage the belt.

Fig. 3: Entrapment point damage

In many cases, proper belt support consists of cradles installed in-line with the carrying idlers to absorb impact and to eliminate fluctuations at the belt line. The key, then, is to utilize bar cradles or slider beds that support the belt evenly through the loading zone until the load is settled.

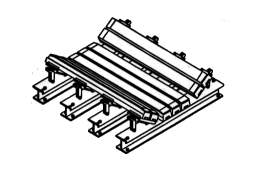

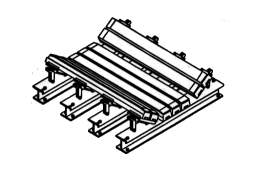

Impact-absorbing systems placed under the load zone with entry and exit idlers allow large impacts, yet prevent the belt sag (Fig. 4). This support system features a slick top cover to allow the belt to slide across along with underlying layers of rubber to absorb the impacts.

Fig. 4: lmpact absorbing belt support cradle

Fig. 5: Side-seal bell support cradle, with conter roliers to reduce friction

Lighter duty side-seal cradles can be used in the non-impact areas (Fig. 5). Placed directly under the chute wall/skirting seal system to maintain an effective seal, these support systems provide a long life and slick wear surface. Combination cradles, incorporating closely spaced rollers in place of some or all bars are endorsed for some applications.

Intermediate idlers should be used in conjunction with the belt support systerns to reduce the power consumption of the conveyor system.

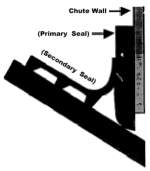

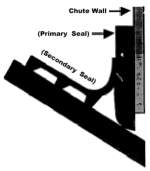

Wear Liner

Wear liner is a flat sacrificial surface Maced inside the chute wall to form a longlasting barrier to protect the edge seals (Fig. 6). If left uncontrolled, side Loading of the material places tremendous pressures on the seal. This leads to accelerated wear of the sealing strip, in turn to spillage, and the risk of major belt damage. But the wear liners inside the chide form a line of defense to shield the sect from the forces of the material load.

Liner materials could be mild or stainless steel, abrasion-resistant plate, ceramic faced or hard-faced steel, rubber, urethane, or plastic, depending on the specifies of the application.

liners can be installed against the chute walls, or with an open area between the actual wall and the wall. This spaced wear liner is then used as a pickup area for the dust collection system, or as auxiliary free area to shelter the sealing system from loading material.

For all wear liners, the cross-sectional area of the chute should be checked carefully to make certain that the liner does not interfere with flow. It is critical that wear liners be installed as a smooth seamless layer that widens in the direction of belt travel, to minimize material entrapment and the risk of belt damage. Great attention must be given to the bottom edge to avoid pinch points that can entrap material and injure the moving belt.

Fig. 6: Wew liners are installed inside the chute to protect the sealing stops from material forces

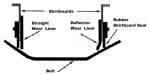

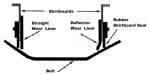

Skirtboard Seal

Over the years, elastomer strips have been used as a seal along the side of the load zone. But these strips have met with problems in maintaining effective sealing performance. Too often, they were expected to bear the total responsibility of containing the material load. Expecting these thin, flexible strips to contain large volumes of material over long periods of time is begging for failure.

However, once belt support and wear liner have been correctly installed, the seals at the sides of the load zone now need to contain only small particles fines and dust - a job the elastomer sealing strips are more suited to perform.

Fig. 7: Multiple-layer waling system using two stops of elastomer

Like multiple layers of clothing protect the body in cold weather, multiple barrier sealing systems form several lines of defense (Fig. 7). An effective sealing system provides two layers of elastomer: a primary seal against the chute wall, to prevent the escape of most particles, and a secondary seal that lies on the belt surface outside the chute, to prevent dust from escaping the system. Tensioned against the belt by its own internal resilience, this multiple layer sealing system requires only occasional maintenance to keep sealing performance at maximum.

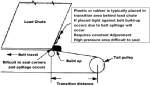

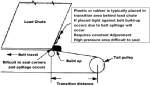

3.1.3 - Entry Area Sealing

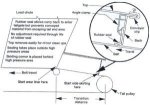

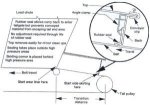

Sealing of the belt entry in the load zone is a consistent problem (Fig. 8). If the seal at the conveyor's tail end is loosely applied, loading material will escape out it, rolling back down the transition area onto the floor. But if the sealing system is against the belt tight enough to prevent this leakage out the back of the loading zone, the sealing strip acts a belt cleaner, removing any residual material from the belt that then runs down the conveyor to accumulate at the foot of the conveyor.

A better approach is to seal this area behind the load zone with a multiple barrier tailgate box (Fig. g). This box seals the entry area behind the load zone. A sealing strip on the inside of the sealing box forms a one-way seal to prevent material roliback. Deflected in the direction of belt travel (Fig. 1 0), this tail seal effectively stops material roliback while preventing build-up from the belt cleaner effect. The dust seal on the sides of the loading chute should start well behind the actual load zone and run continuously from the entry area to the end of the skirtboard. This eliminates the problem of sealing the high-pressure corners of the impact zone.

Fig. 8: An overview of the problem of entry area sealing

Fig. 9: Applied at the back of the loading chute, a tailgate sealing box uses a tail sealing strip that deflects in the direction of belt travel

Fig. 10: An overview of the solution to entry area sealing

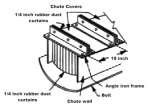

Fig. 11: Dual exit curtain dust sad

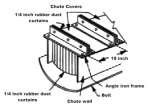

3.1.4 - Exit Area Sealing

Effective dust sealing at the exit end of the skirtboard requires dual rubber curtains. These are hung roughly 18 inches (450 mm) apart to form a "dead" area where dust can settle. The curtains should be composed of slit rubber and extend to approximately one inch (25 mm) below the top of the pile of product on the belt (Fig. 11). This baffier then deflects when material is running, yet closes down when there is a void in the material.

3.1.5 - Chute leakage

Often areas contributing to fugitive material are overlooked. Load chutes with holes from rust or abrasion can allow significant amounts of material to escape. Even the holes created by missing bolts and open access doors can allow a visible stream of airborne dust to escape. For total dust control, it may be necessary to replace an entire loading chute.

As the exit of the transfer point represents the "last chance" for the three dust control sub-systems, it is important that the chute work and the three systems be carefully engineered to work together.

3.2 - Dust Suppression Systems

Dust suppression is the application of water or chemically-treated-water in some manner of spray, fog, or foam to prevent fines from being driven off the material body into the air. There are a number of mechanical systems used for this purpose, ranging from "garden hose" technology to sophisticated, engineered systems.

3.2.1 - Water

Perhaps the oldest system for holding down dust is the application of water in a spray over the body of material. The suppression effect is achieved by adding to the moisture content of the material, altedng the weight/mass ratio and cohesiveness of the material. By wetting the dust, either as it lies in the material body or as it escapes off the pile, the gravity of each particle is increased, so it is less likely to become airborne. The moisture also increases the cohesion of the material, making it more difficult for air currents to pick up particles.

The effectiveness of wet suppression systems varies widely, depending on application techniques, amount of moisture added, and material characteristics.

High volume/high-pressure spray systems should be avoided, as the energy of the water spray will transfer to the material particles, producing dust rather than controlling it.

When applying moisture to conveyor belts, a good axiom is "less is more". The volume of water applied is typically in the range of 0.5% to 4% moisture added to the material. Excess water may promote belt slippage and increase the possibility of wet (and hence sticky) fines accumulating within chutes and around transfer points. Excessive moisture can adversely aftect the matetial's "cold weather" perforrnance, complicate its flow dynamics, add weight (and hence cost) to material transportation, and reduce the effectiveness of conveyor belt cleaning systems.

In addition, in some processes such as coal-fired power generation, excess moisture reduces material performance.

3.2.2 - Chemical Additives

A number of supjdiiers offer chemicals to be added to the water systems. These chemicals act as wetting agents, making the water "wetter" to increase its dust "attraction" and holding ability. These suppressants offer certain advantages, but there are drawbacks that should be considered. These concerns include the additional (and continuing) cost of the additive and the impact of the chemical on the material's eventual use.

3.2.3 - Foam

Foam dust suppression works effectively by reducing the surface tension or "static charge" of individual dust particles and increasing the molecular attraction between fugitive dust particles and the material mass. The foam is generated by mixing foaming surfactants, water, and compressed air in proper proportions. Application of foam dust suppression into transfer chutes and crushers can increase immediate and mid-term dust suppression through several transfer points and stack-out operations. Foaming surfactants with "residual agents" can increase the dust suppression effect over longer storage or transportation periods, such as stockpiling or shipping. Moisture addition from foam dust suppression systems ranges from 0.08% to 0.2% by weight. At these reduced levels of added moisture, the adverse affects associated with excess moisture are greatly reduced or eliminated.

3.2.4 - Fog

Fog suppression systems are a recent improvement on water sprays. These systems produce extremely small water droplets in a dispersed mist to capture dust particles. Fog suppression is based on the knowledge that droplets must be the same size as the dust particles to effectively combine with them. If the droplets are too large, smaller dust particles can "slipstream" around them. Fog systems break water down into very fine particles that agglomerate readily with airborne dust. The increased weight of the combined particles causes them to settle back into the main material stream. Fog systems add low volumes of water less than 0. 1 % of the material - to avoid degrading the material.

There are two methods of producing the water-mist fog. One system mixes water with compressed air through a two-fluid nozzle. The second system uses water pumped at high pressure through single fluid atomizing nozzle. This second system does not require compressed air or any external power Source, other than the electricity to run the pump. By eliminating the compressed air requirement, this system simplifies installation and reduces operating costs.

3.2.5 - Reduction in Air Movement

A variable that can be controlled to improve the effectiveness of dust suppression is to slow the air movement within the loading zone. If the air velocity is too high, particles carried on the air currents avoid the water molecules, "slipstreaming" away from them in the same manner a motorcycle on a highway is pushed away from a semi-truck. One way to overcome this is the addition of more water, but this can have side effects which downgrade the performance or value of the material. A better approach is to slow down the movement of air (and the particles it is carrying) below 2C)0 ft/min (1 mlsee) by increasing the size of the enclosure. This large enclosure serves as a plenum where air velocity can dissipate.

3.3 - Dust Collection Systems

Dust collection - the passing of air carrying dust from the load zone through some form of filtration system - is the final piece in our pyramid of dust control systems. There are passive systems, which merely allow the air to pass through the filters, and active systems, which pull the air in like a vacuum cleaner to remove solids.

Any conveyor system will have a number of dust creation points that may require dust collection. The size and cost of a dust collection system are directly related to the volume of air that must be pulled through the system. The correct assessment of this required air volume is, therefore, fundamental to efficient and economical dust collection.

If these positive pressures are not addressed with proper relief or correct dust collection sizing, the particles of dust will be forced out of the conveyor system by the flow of air. There are three types of air movement that might be present: displaced air, induced air, and generated air.

Total air flow in a given transfer point can be determined with the following equation:

Qtot = Qgen + Qdis + Qind

where:

Qtot = total air movement (ft3/min)

Qgen = determined generated air (ft3/min)

Qdis = calculated displaced air (ft3/min)

Qind = calculate induced air (ft3/min)

3.3.1 - Displaced Air

When coffee is poured into an empty cup, the air inside is.displaced by the coffee. The same effect occurs when the load chute is filled with conveyed product: the air in the chute is displaced by the material. The amount of this displaced air increases with the size of the load chute and the volume of material moving through it. To calculate the displaced air:

Qdis = conveyed product (lb/min)

bulk density (lb/ft3)

lb/min = t/h x 2000

60

3.3.2 - Induced Air

Conveyed material lying on the belt and traveling along the belt will have a small amount of air entrapped in the product bed. As the material leaves the head pulley in the normal trajectory, the body of product becomes larger, as each particle of material collects an amount of air. When the conveyed product lands, this induced air is then released, causing substantial positive pressure flowing away from the center of the load zone.

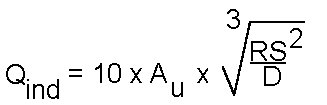

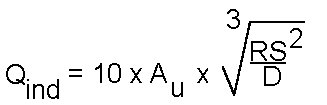

The following method is used to calculate the movement of induced air.

Qind = calculate induced air (ft3/min)

Au = enclosure open area at upstream end (ft2)

(at the point where air is induced into system by action of failing material)

R = rate of material flow (t/h)

S = height of material free fall (ft)

D = average material diameter (in ft)

3.3.3 - Generated Air

Another source of moving air may be devices feeding the load zone such as crushers, wood chippers, hammer mills, or any device, where turning creates a fan-like effect. To determine the amount of air generated by this equipment, the end user should contact the manufacturer. Another, more challenging solution is to actually measure this air flow.

A mechanical dust collection system will be required when the total air flow in the loading zone exceeds 1,000 ft3/min (28,320 l/min). This total air movement must be compensated for by the installation of a mechanical dust collection equipment equal to or greater than the value of the total air flow.

3.4 - Engineering Dust Collection Systems

After each dust creation point is evaluated, and the quantity of air to be processed from each point is estimated, then the type of dust collection system should be selected. There are three basic approaches to dust collection systems: central, unit, or integrated systems. The central method of handling dust collection would be to connect all the individual collection points by means of ducting to a single filter in a single, more-or-less remote location. The unit concept consists of small, self-contained dust collectors for individual or small and conveniently grouped dust generation points. A logical extension of the unit concept is the integrated system, where insertable filters are installed within the dust generation point itself.

If the total air movement - the total of displaced, induced, and generated air - is not considered when selecting the chute wall dimensions, severe velocities will be created. If the enclosure is too small, air will be forced from the high pressure area inside the enclosure through any opening to the lower pressure outside. Pushed out by the pressure of the generated and induced air, this air will pick up speed until it picks up dust particles to carry outside the system.

It is important that the material fines be allowed a chance to settle, either of their own accord or due to a water spray or fog system, before the collection points (take-offs) are installed. Otherwise, energy will be wasted removing dust that would have shortly settled on its own, and the dust collection system will be larger (and more expensive) than necessary.

The transfer point's skirtboard should be of sufficient height and length to serve as a plenum to contain the dust giving it time to settle. The goal is to make the enclosure large enough that the air velocity is below 200 ft/min (61 m/minute). A good rule-of-thumb for length is two feet per hundred feet of belt speed on belts with minor air movement. On belts with large calculated air movement, the transferpoint length should approach three feet per hundred feet of belt speed. Chute walls need to be high enough to stop air pickups pulling fines off the pile.

Multiple dust collection pick-up points are usually required. A common practice is to locate one pick up at the entry area behind the load zone, to remove approximately one-fourth the total calculated air movement, and to install a second dust collection pick up at approximately two belt widths after the loading chute, to collect the remaining three-fourths of the air movement.

It is critical that collected dust be returned into the main material body in a manner that avoids re-energizing the dust back into the air.

Section 4: - Three Systems Into One Solution

The key to success in dust control is to provide proper containment first. Analyzing the load zone to identify areas contributing to the escaping material should be the first step in reducing the dust emissions. After material is contained in the system, the proper application of dust suppression and collection will result in effective control of fugitive material.

Given their individual differences, transfer points require individual solutions to control fugitive material. The reasonable answer to fugitive dust arising from belt conveyors is to form a dust control "triad" of all three systems - containment, suppression, and collection - working together. An in-depth look at how fugitive material is generated will supply the information needed to devise a solution that prevents fugitive material at any specific transfer point.

There are many options and variables within each of these three systems - almost as many variables as there are transfer points. It is essential the three systems all be considered carefully, individualiy and together. A craftsman understands the need for and the use of each of the different tools in his toolbox. A golfer does not know in advance which of his clubs will be required on a given round, but the skilled golfer knows how and when to use each club in specific circumstances. Similarly, the solution to fugitive material will require the wise selection and effective use of each of the three basic systems of dust control.