No. of Plies |

Mass Thickness |

Belt Class |

|||||||||||

200 |

250 |

315 |

400 |

500 |

630 |

800 |

1000 |

1250 |

1600 |

2000 |

2500 |

||

2 |

All - kg/m2 |

3,3 |

3,8 |

4,8 |

4,9 |

6,3 |

6,3 |

- |

- |

- |

- |

- |

- |

3 |

All - kg/m2 |

4,4 |

4,4 |

5,4 |

5,0 |

5,0 |

5,5 |

7,6 |

7,6 |

- |

- |

- |

- |

4 |

All - kg/m2 |

|

|

6,2 |

6,2 |

7,0 |

7,0 |

7,1 |

10,3 |

10,3 |

- |

- |

- |

5 |

All - kg/m2 |

|

|

|

8,0 |

8,0 |

8,9 |

8,9 |

9,0 |

13,1 |

13,1 |

- |

- |

6 |

All - kg/m2 |

|

|

|

|

9,8 |

9,8 |

10,9 |

10,6 |

10,6 |

15,8 |

15,8 |

- |

????????????????????????????????

Table recommends take-up travel distance for Plylon fabric belts as a percentage of pulley center distance.

PLYLON

FABRICTYPE OF

TAKE-UPFASTENED SPLICE

VULCANISED SPLICE

100% of

Rated tension75% or less of

Rated Tension100% of

Rated Tension75% or less of

Rated TensionAll Nylon

Screw

Auto1,5%

2,0%1,0%

1,5%4,0%

2,5% + 0,6m3,0%

2,5% + 0,6mE.P.

Screw

Auto1,5%

1,0%1,0%

1,0%4,0%

1,5% + 0,6m3,0%*

1,5% + 0,6mNote:-

'*' Only short endless feeder belts and the like would normally be vulcanised on conveyors with screw take-up.Idler Spacing

Table indicates typical troughing idler spacing / pitch for various material bulk densities and belt widths

BELT WIDTH W (mm)

BULK DENSITY (tons/m3.)

Under 0,8

0,8 to 1,6

Over 1,6

600

750

900

10501,70

1,59

1,51

1,441,43

1,32

1,23

1,171,27

1,15

1,07

1,011200

1350

1500

1800

21001,40

1,35

1,31

1,24

1,191,12

1,08

0,04

0,98

0,930,97

0,93

0,90

0,84

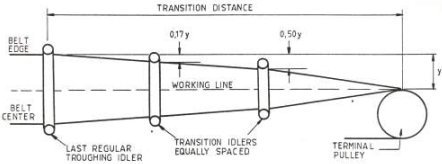

0,80Transition Lengths

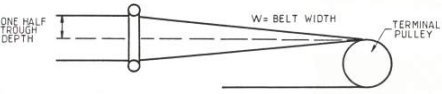

Table 1 indicates the recommended transition distance for half-troughed conveyor applications.

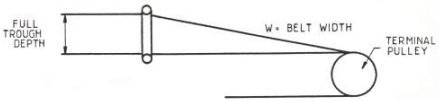

Table 2 indicates the recommended transition distance for full-troughed conveyor applications.

Table 3 indicates the number and location transition idlers.Table 1 - Transition distance for half-trough depth.

TROUGH ANGLE (deg.)

PERCENTAGE OF RATED TENSION

FABRIC BELTS

STEEL CABLE BELTS

20

MORE THAN 90

60 to 90

LESS THAN 600,9w

0,8w

0,6w2,0w

1,6w

1,0w35

MORE THAN 90

60 to 90

LESS THAN 601,6w

1,2w

0,9w3,4w

2,6w

1,8w45

MORE THAN 90

60 to 90

LESS THAN 602,0w

1,6w

1,2w4,0w

3,2w

2,2wNote:-

All conveyors using troughing idlers with angles greater than 20 adjacent to terminal pulleys shall have transition idlers between the given terminal pulley and the nearest standard idler.

Table 2 - Transition distance for full-trough depth.

TROUGH ANGLE (deg.)

PERCENTAGE OF RATED TENSION

FABRIC BELTS

STEEL CABLE BELTS

20

MORE THAN 90

60 to 90

LESS THAN 601,8w

1,6w

1,2w4,0w

3,2w

2,0w35

MORE THAN 90

60 to 90

LESS THAN 603,2w

2,4w

1,8w6,8w

5,2w

3,6w45

MORE THAN 90

60 to 90

LESS THAN 604,0w

3,2w

2,4w8,0w

6,4w

4,4wNote:-

All conveyors using troughing idlers with angles greater than 20 adjacent to terminal pulleys shall have transition idlers between the given terminal pulley and the nearest standard idler.Table 3 - Number and Location of transition idlers

NUMBER OF TRANSITION IDLERS

FIRST

SECOND

THIRD

FOURTH

1

0,33Y

2

0,17Y

0,50Y

3

0,10Y

0,30Y

0,60Y

4

0,07Y

0,20Y

0,40Y

0,67Y

Stringer Widths

Table indicates standard stringer widths for different belt widths.

BELT WIDTH

(mm)PULLEY FACE

WIDTH

(mm)STRINGER BOLT HOLE

CENTRE DISTANSESSTANDARD

RANGE

(mm)WIDE

RANGE

(mm)300

400

400

500

634

-

450

550

686

-

500

600

736

-

600

700

838

965

750

900

990

1118

900

1050

1144

1270

1050

1200

1296

1422

1200

1350

1448

1575

1350

1500

1600

1727

1500

1700

1752

1880

1650

1850

1904

2030

1800

2000

2058

2184

2100

2300

2362

2489

2400

2600

NOTE: This table agrees with the provisions of SABS 1313-1980 with respect to "standard" range centres only.

"Wide range" centres are not mentioned in this specification.